3.0 Types of Laser Welding (Fiber, CO₂, Hybrid, Ultrafast)

Introduction

The technology of laser welding has advanced significantly from its early use as a specialist procedure. These days, it has expanded to include several kinds of lasers and welding methods, each of which is tailored for particular materials, thicknesses, joint types, and industries. Maximizing efficiency, quality, and cost-effectiveness requires selecting the appropriate kind of laser welding technology.

We shall examine the main categories of laser welding technology in detail in this guide:

- Welding using Fiber Laser

- Welding using CO₂ Lasers and Hybrid Lasers

- Ultrafast Femtosecond and Picosecond Laser Welding

To assist you in making an informed choice, we will go over their benefits, drawbacks, and best-fit applications.

1. Fiber Laser Welding

What is Fiber Laser Welding?

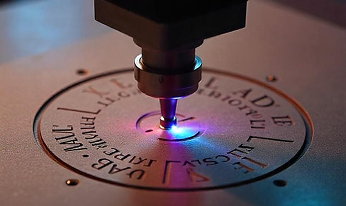

A state-of-the-art technique called fiber laser welding uses laser light produced by a solid-state laser source and sent to the welding head via flexible fiber optic cables. Extremely high power densities are produced at the work surface by focusing the laser beam into a very compact area. The metals at the junction are melted by this concentrated energy, and when they solidify, they fuse together to form a precise and robust weld.

Because of its effectiveness, versatility, and suitability for a range of sectors, this technique is currently the most sophisticated and extensively utilized type of laser welding. Fiber lasers provide outstanding beam quality, which results in thin weld seams, deep penetration, and high-speed welding.

The small size and sturdy construction of fiber lasers are further benefits. These systems are widely used in heavy machinery, electronics manufacturing, automotive, and aerospace industries because they are simple to incorporate into robotic arms and automated production lines due to the fiber optic cables that convey the beam.

In addition to supporting a large variety of materials, such as mild steel, stainless steel, titanium, aluminum, and even reflective metals (with some modifications), fiber laser welding systems are also quite powerful and adaptable in industrial settings.

Principal Benefits:

- High electrical efficiency (conversion efficiency of up to 50%).

- Narrow seams and deep penetration are made possible by superior beam quality.

- A sturdy, small design that requires little upkeep.

- The capacity to fuse thick and thin metals at high speeds.

Restrictions:

- Copper and brass are examples of reflective materials that need certain wavelengths or power management.

- A little more expensive initially than more traditional laser kinds.

Top Uses:

- Parts of the car's body and chassis.

- Structures and fuel systems in aerospace.

- General metal manufacturing and industrial machinery.

- Modules and casings for EV batteries.

Fiber Laser Welding Systems from Laser Technologies India are specialized for automotive and aerospace production, giving precision, speed, and versatility.

2. CO₂ Laser Welding

What is CO₂ Laser Welding?

One of the oldest and most well-known types of laser welding is CO₂, which uses carbon dioxide gas as the laser medium. This system creates infrared light with a wavelength of around 10.6 micrometers by electrically stimulating a mixture of CO₂, nitrogen, and helium gases. After that, the laser beam is focused on the material to be welded via a sequence of mirrors and focusing lenses.

CO₂ laser welding works especially well on thin sheet metals and non-metallic materials due to its larger wavelength. Because fiber lasers are more energy efficient and require less maintenance, they have supplanted CO₂ lasers in the majority of metal welding applications.

How It Operates:

- Reflective mirrors are used to steer the produced laser beam.

- The beam is converged into a narrow point by a focusing lens, producing a high energy density.

- Parts can fuse together because the substance is melted by this focused heat.

Typical Characteristics:

- Polymers and plastics: Found in consumer gadgets, packaging, and car interiors.

- Thin metals: Sheets of aluminum and stainless steel for ornamental purposes, for instance.

- Medical equipment: In particular, when clean, smooth welds are crucial.

Important Sectors and Uses:

- Plastics and polymers: Used in automotive interiors, packaging, and consumer electronics

- Thin metals: For example, stainless steel and aluminum sheets for decorative applications

- Medical equipment: Especially where smooth, clean welds are essential

Even though CO₂ lasers are less successful than fiber lasers at welding thick and reflective metals, they are nonetheless useful instruments in applications where cost-effectiveness and extremely clean weld surfaces are essential.

Restrictions:

- Reduced energy efficiency.

- More upkeep is needed (optics alignment and cleaning).

- less depth of penetration in metals than fiber lasers.

Although fiber lasers are gradually replacing CO₂ lasers in metal welding, CO₂ lasers are still widely used for non-metallic materials and legacy production lines.

3.Hybrid Laser Welding

What is Hybrid Laser Welding?

Hybrid laser welding is a potent and innovative method that combines two welding processes into one cohesive procedure: laser welding and conventional arc welding techniques (usually MIG or TIG welding). Hybrid laser welding combines the advantages of both technologies to produce better outcomes than any method could on its own.

The arc welding source provides extra heat and filler material, and the laser beam is directed onto the joint to produce deep penetration and rapid welding speeds. Better gap-bridging ability is made possible by this synergy, which is frequently difficult in conventional laser welding that calls for extremely precise joint tolerances.

How Hybrid Laser Welding Operates:

- A deep, narrow keyhole is created at the seam when the metal is melted by the laser beam.

- In order to make up for any gaps or differences in joint fit-up, filler metal is simultaneously added to the joint using the arc welding technique (MIG or TIG).

- The combination of heat sources enhances the final weld's metallurgical qualities and stabilizes the welding process.

Benefits:

- The benefits of hybrid laser welding include its ability to fuse thick materials deeply while preserving high travel speeds.

- Allows for wider joint gaps and shoddy fit-ups without sacrificing the quality of the weld.

- Decreases manufacturing costs overall and eliminates the necessity for exact joint preparation.

Common Uses:

Industries where cost-effectiveness, productivity, and structural integrity are critical use hybrid laser welding:

- Large, thick steel plates with a range of fit-up criteria are welded in shipbuilding and offshore construction.

- Connecting lengthy stretches of track and vehicle bodies is known as railway manufacturing.

- Automotive body-in-white: combining robust, consistent weld seams with high-strength steel panels.

Fiber laser-powered hybrid solutions from businesses like Laser Technologies India are essential to modern manufacturing, and hybrid laser welding is quickly becoming a favored option in heavy industry sectors where attaining both quality and production speed is crucial.

4. Ultrafast Laser Welding (Femtosecond & Picosecond)

What is Ultrafast Laser Welding?

Ultrashort laser pulses, usually in the femtosecond (10⁻¹⁵ seconds) or picosecond (10⁻¹² seconds) range, are used in ultrafast laser welding, a highly sophisticated technique. Ultrafast lasers, as opposed to continuous wave or long-pulsed lasers, emit energy in remarkably short bursts that minimize thermal energy transfer to the surrounding material while producing exceptionally high peak power.

This process, which is sometimes called "cold welding" or "non-thermal welding," produces clean, accurate connections with very small heat-affected zones (HAZ). When working with delicate, thin, or heat-sensitive materials, the quick pulse eliminates problems like warping, microcracking, or material degradation by preventing heat from transferring into nearby areas.

The material reacts with the intense light energy during ultrafast laser welding through nonlinear absorption mechanisms. This makes it possible for the laser to even weld materials that are often exceedingly difficult to weld using traditional techniques, such as glass, sapphire, and polymers, which are clear and highly reflecting.

Ultrafast laser welding is especially appropriate for cutting-edge applications in medical device production, electronics, fine jewelry, micro-mechanics, and aerospace, where micro-scale joining and aesthetic perfection are crucial because of its exceptional precision and low heat input.

Principal Benefits:

- Heat-affected zone (HAZ) that is almost zero.

- Precision at the micron level appropriate for microwelding.

- Welds clear materials, such as plastics and glass.

- Ideal for extremely thin and delicate materials.

Limitations:

- The equipment is extremely expensive.

- Reduced welding productivity and speed for large components.

Applications:

- The best uses are for microsurgical tools and medical stents.

- Electronics (micro-connectors, MEMS, sensors).

- Expensive jewelry and watch parts.

The cutting edge of precision joining technology is represented by ultrafast lasers, which can accomplish impossible welds that traditional lasers are unable to.

| Laser Type | Best For | Key Advantages | Limitations |

|---|---|---|---|

| Fiber Laser | Metals (thin and thick), automotive, aerospace | High speed, high efficiency, deep penetration | Reflective materials need special handling |

| CO₂ Laser | Non-metals, plastics, thin metal sheets | Smooth welds, lower cost | Lower efficiency, high maintenance |

| Hybrid Laser | Heavy industries, large parts | Tolerant to gaps, deep penetration | Complex setup, expert control needed |

| Ultrafast Laser | Micro-welding, sensitive materials | Ultra-precise, no HAZ | High cost, slow for large parts |

Conclusion

Every kind of laser welding technology has certain advantages that are appropriate for various sectors and applications:

- Because of their speed, accuracy, and adaptability, fiber lasers are the industry standard for manufacturing.

- CO₂ lasers are still used in thin-material and non-metallic applications.

- In heavy industry, where joint tolerances and strength requirements are crucial, hybrid lasers fill the gap.

- In the fields of micromanufacturing, electronics, and medicine, ultrafast lasers are opening up new possibilities.

The future of laser welding is shifting toward more automated, intelligent, and environmentally friendly systems thanks to developments in artificial intelligence, adaptive optics, and real-time process monitoring.

At Laser Technologies India, our product lineup covers every need — from high-powered fiber lasers for automotive lines to specialized ultrafast lasers for medical device manufacturers.

To find the ideal laser welding solution for your company's requirements, get in touch with us right now! "Laser Welding in Automotive Industry" is the next topic in Laser Welding University.