8.0 Laser Welding vs Traditional Welding (TIG, MIG, Spot Welding)

Introduction

Numerous welding techniques have been employed for decades in the field of metal joining. Many businesses still use conventional methods like spot welding, metal inert gas (MIG), and tungsten inert gas (TIG). But as production needs and precision standards have changed, laser welding has become an innovative substitute.

In order to assist producers in making well-informed decisions, this article compares laser welding with conventional welding techniques on important characteristics such as precision, speed, heat input, material compatibility, and cost.

1. Understanding the Welding Processes

TIG Welding

- Uses a non-consumable tungsten electrode and inert gas (usually argon).

- Known for precise control and high-quality welds.

- Thin portions of non-ferrous metals, aluminum, and stainless steel work best.

MIG Welding

- Employs a welding gun to feed a consumable wire electrode.

- Ideal for thicker materials, it is quicker and simpler than TIG welding.

- Needs shielding gas in order to keep the weld pool safe.

Spot Welding

- Thin metal sheets are joined using the resistance welding technique

- Frequently found in auto bodywork.

- Fast method, but only works with overlapping sheets.

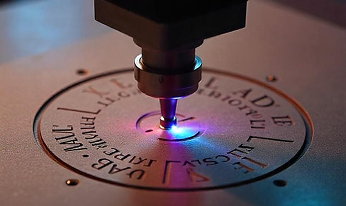

Laser Welding

- Melts and fuses materials using a focused laser beam.

- Incredibly quick and accurate with minimal heat input.

- Ideal for reflecting materials, alloys, and thin to thick metals.

2. Comparison Table: Laser Welding vs Traditional Welding

| Criteria | TIG | MIG | Spot | Laser Welding |

|---|---|---|---|---|

| Precision | Excellent | Moderate | Low-Moderate | Superior (micron level) |

| Speed | Slow | Fast | Very Fast | Very Fast |

| Heat Input | High | High | Localized | Low (narrow HAZ) |

| Material Thickness | Thin to medium | Medium to thick | Thin | Thin to thick |

| Automation | Difficult | Moderate | Easy | Very Easy (robotic/CNC) |

| Post Processing | Often needed | Often needed | Minimal | Minimal to none |

| Cost per Weld | High labor | Moderate | Low | Low (in high-volume) |

3. Benefits of Laser Welding Over Traditional Methods

- Increased Accuracy and Quality: Narrow, minimally distorted welds. Ideal for uses requiring precise tolerances.

- Increased Processing Speeds: Rapid welding is made possible by high power density. Ideal for automated lines and large-scale production.

- Reduced Heat Input: Lessens distortion, particularly in delicate and thin areas. Metallurgical characteristics are improved by a smaller heat affected zone (HAZ).

- Simple Integration and Automation:The non-contact method is easily integrated into robotic cells. Meets the needs of Industry 4.0 and smart manufacturing.

- Adaptability: Able to fuse reflective materials, metals, alloys, and even non-metals (with certain lasers).

Applications requiring accuracy, speed, and automation are ideal for laser welding. The most benefited industries include electronics, automotive, aerospace, and medical.

4. When Conventional Welding Continues to Succeed

Conventional techniques might not always be replaced by laser welding. In some situations, spot welding, MIG, or TIG are more useful:

- Low Volume Production: Initial investment in laser welding may not justify the cost.

- Thick Structural Welds: For extremely thick and structural steel components, MIG and TIG welding continue to offer benefits.

- Complex Filler Requirements: Arc welding is a superior option for processes that call for the deposition of heavy filler metal.

- Repairs and Field Work:Traditional welding is superior for on-site repairs due to its portability and flexibility.

While older technologies are still useful for heavy fabrication and low-volume, cost-sensitive applications, laser welding is the best option for precision and production speed.

Conclusion

Although laser welding is a potent addition to the metal joining tools, it cannot fully replace conventional welding. Laser welding is becoming more and more popular as companies continue to automate and look for higher quality at cheaper costs because:

- Extremely quick production.

- Accurate joining.

- Decreased post-processing.

- Smooth interaction with CNC and robotic systems.

Heavy-duty, low-volume, and intricate filler welding applications continue to benefit greatly from the use of conventional welding techniques including TIG, MIG, and spot welding. However, laser welding provides unrivaled speed, accuracy, and automation readiness benefits for high-volume industries including electronics, automotive, aerospace, and medical.

Advanced laser welding solutions from Laser Technologies India are available to assist manufacturers in smoothly switching from conventional to intelligent laser-based joining procedures.