12. Best Software for Laser Welding Machine Operation

Introduction

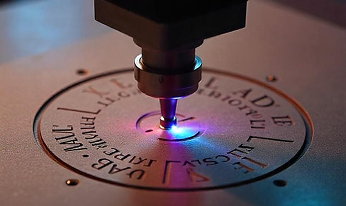

Software is what makes a laser welding equipment work, even though hardware is its fundamental component. The correct software is essential for guaranteeing accuracy, consistency, and productivity in everything from controlling welding parameters to automating complicated procedures and integrating with manufacturing ecosystems.

Understanding the different kinds of software and how they affect operations is crucial for businesses striving for superior results as laser welding develops into an intelligent, automated process.

The Significance of Software in Laser Welding

- Parameter Management: Control of laser power, shielding gas, speed, focus, and pulse duration is known as parameter management.

- Recipe Storage:Store and retrieve welding programs for various materials and products.

- Automation Integration: Communicate with robotic systems and CNC controllers.

- Quality Assurance: Log process parameters for process validation and traceability in quality assurance.

- User Experience: Training time and operator error are decreased with intuitive interfaces.

In addition to making the process simple and scalable, sophisticated software guarantees accuracy and consistency.

Types of Software Used in Laser Welding Machines

CNC & Motion Control Software

- Motion control software and CNC software regulate machine motion and guarantee precise path following.

- Both 2D and 3D welding pathways are supported.

- Enhances welding synchronization, acceleration, and travel speed.

The software for laser process control

- Establishes laser-specific parameters such as frequency, power, and pulse form.

- Real-time beam focus and modulation adjustments are made.

- Connects to sensors to provide adaptive welding.

Vision and Seam Tracking Software (AI-Enabled)

- AI-enabled Vision and Seam Tracking Software detects joint positions using cameras and sensors.

- Automatically modifies the settings and welding path.

- Minimizes rejects brought on by variations or misaligned parts.

Factory Integration Software (MES / ERP Connectors)

- Welding machines and plant management systems are connected by factory integration software (MES/ERP connectors).

- Permits data analytics, remote monitoring, and production scheduling.

- Supports Smart Factory and Industry 4.0 settings.

Every software layer contributes to data-driven manufacturing, automation, and total control.

Features to Look for in Laser Welding Software

- Interface for Easy Programming: Graphical user interface (GUI) for quick learning and easy use.

- Weld schedules that are customizable: the capacity to save and retrieve various parameter sets.

- Dashboards for live monitoring: graphical representations of weld productivity, quality, and status.

- Automatic Error Detection: Notifications of alignment concerns, gas problems, or power variations.

- Data reporting and logging: Historical documentation for compliance, audits, and process enhancement.

- Remote Access and Control: Use a network or cloud to remotely monitor and adjust welding jobs.

An effective software platform strikes a balance between robust control, ease of use, and intuitive design.

Software Solution Examples (Global + Laser Technologies India)

- Laser Technologies India - Integrated Laser Welding Software

- User-friendly GUI

- Parameter library

- Seam tracking integration

- Siemens Sinumerik & Beckhoff CNC Controllers

- Motion and path control that is industry standard

- Ready for automation and simple to integrate with MES systems

- IPG LightWELD Software (Ultrafast & Handheld Lasers)

- Portable UI

- Preset weld programs

- AI-Powered Vision Systems (Integrated in Robotics)

- Path rectification and seam finding

- Adaptive welding and defect detection

Your laser welding machine will be future-proof and ready for production if you choose the correct software ecosystem.

Conclusion

Software is becoming more and more important as laser welding gets more sophisticated and integrated. Intelligent software makes laser welding smarter, faster, and more dependable by controlling robotic arms, checking weld quality, and establishing connections with corporate systems.

- Process control software guarantees accuracy and consistency.

- Complex and quick welding pathways are made possible by automation and CNC software.

- AI and Vision Systems: Prevent human error and guarantee excellence.

- Laser welding is introduced into digital manufacturing through integration software.

End-to-end laser welding solutions from Laser Technologies India are supported by user-friendly and robust software platforms that streamline operations while optimizing quality and performance.

"Purchasing Guide & Cost Analysis of Laser Welding Machines" is the next course at Laser Welding University