9.0 Best Laser Welding Machines for Industrial Use

Introduction

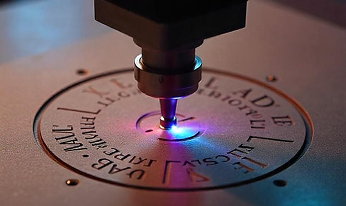

Selecting the appropriate laser welding machine can have a significant impact in the fast-paced, precision-driven industrial environment of today. Machines that provide dependability, speed, flexibility, and excellent weld quality are needed by a variety of industries, including heavy machinery fabrication, medical device manufacture, and automobile production lines.

This guide will help you discover what makes the best industrial laser welding machines unique, which types are suitable for specific industries, and how to choose the best model for your needs.

1. What Makes a Laser Welding Machine the “Best”?

Not every machine is made equally. The following crucial areas are where a genuinely superior laser welding machine shines:

- Accuracy & Precision: Repeatable, high-quality welding with micron-level control.

- Efficiency and Speed: High welding speeds without sacrificing the integrity of the weld.

- Material Flexibility: Ability to weld a broad range of metals and alloys

- Automation Capability:Smooth interaction with intelligent manufacturing and robotic systems.

- Ease of Use: Simple parameter settings and intuitive software make it easy to use.

- Reliability and Serviceability: designed for industrial settings that are open around-the-clock.

2. Types of Laser Welding Machines for Industrial Use

Fiber Laser Welding Machines (Currently the Most Popular)

- Ideal for: Metals, including titanium, stainless steel, aluminum, and steel.

- Important characteristics: Excellent beam quality, minimal upkeep, and energy efficiency.

- Applications include electronics, heavy machinery, automotive, and aerospace.

For instance, the GH Series Fiber Laser Welders from Laser Technologies India are made for deep penetration, high-speed welding in automated industrial settings.

CO₂ Laser Welding Machines

- Ideal for: Thin metal sheets and non-metals (fabrics, wood, and plastics).

- Important characteristics:Smooth weld joints and reduced starting costs.

- Uses include medical plastics, textiles, packaging, and signage.

Hybrid Laser Welding Machines

- Ideal for: Big structures with gaps and different fit-ups.

- Key features:Combines the accuracy of a laser with the gap-filling capability of arc welding.

- Applications include heavy vehicle fabrication, construction, and shipbuilding.

Rapid Laser Welding Equipment

- Ideal for: Heat-sensitive materials and microwelding.

- Important characteristics: Minimal HAZ, accuracy at the micron level.

- Applications include luxury products, microelectronics, and medical gadgets.

3. Top Laser Welding Machines from Laser Technologies India

Fiber Laser Welding Machines of the GH Series

- Range of power: 1 kW to 30 kW

- Features include CNC integration, automatic control, and high-speed deep penetration.

- Applications include EV batteries, automotive chassis, and aerospace parts.

IMark Series CO₂ Laser Systems

- Enhanced for non-metallic materials and plastics.

- produces crisp, smooth welds without coming into contact with.

Robotic Cells with Laser Welding (Personalized Solutions)

- Robotic robots with many axes for intricate welding routes.

- Perfect for heavy-duty industrial components and automotive body-in-white.

4. Choosing the Right Machine for Your Industry

| Industry | Recommended Laser Machine Type |

|---|---|

| Automotive | Fiber Laser, Hybrid Laser |

| Aerospace | Fiber Laser, Ultrafast Laser |

| Electronics | Ultrafast Laser, Fiber Laser |

| Medical Devices | Ultrafast Laser, Fiber Laser |

| Heavy Engineering / Shipbuilding | Hybrid Laser, Fiber Laser |

Conclusion

A number of considerations must be balanced when selecting the best laser welding machine for industrial usage, including accuracy, speed, material compatibility, automation readiness, and total cost of ownership. Because of their adaptability, fiber laser machines today rule the industrial sector, but CO₂, hybrid, and ultrafast lasers are also crucial in specialized applications.

From the automotive and aerospace sectors to the medical and electronics sectors, Laser Technologies India provides a broad range of cutting-edge laser welding solutions. The characteristics of contemporary industrial laser welding, such as accuracy, robustness, and smooth automation integration, are built into their machines.

"How to Choose the Right Laser Welding Machine for Your Needs" is the next topic covered at Laser Welding University.