2.0 How Does a Laser Welding Machine Work? (In-Depth Guide)

Introduction

Advanced manufacturing relies heavily on laser welding devices. They provide non-contact, high-speed, high-precision welding capabilities for a variety of applications, including the assembly of precision medical devices, high-speed automotive components, and aerospace structures.

However, how precisely do these sophisticated systems function? When a laser welding equipment comes to life, what goes on inside? To help engineers, factory owners, and business decision-makers fully comprehend the technology, we will dissect the basic elements, operation, and workflow of laser welding equipment in this tutorial.

1. What is a Laser Welding Machine?

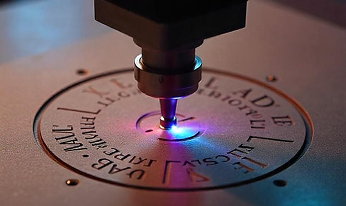

A laser welding machine is an advanced device that uses a concentrated laser beam to combine materials with amazing precision. Laser welding functions as a non-contact procedure in contrast to conventional welding methods like MIG or TIG, which depend on physical contact and the usage of electrodes or filler materials. In addition to enabling highly quick and clean welding operations, this greatly lowers contamination and wear.

Directing a focused laser beam onto the joint between two workpieces is the basic operating principle. The material absorbs the laser's high energy, which quickly raises its melting point. The molten pool solidifies as the laser passes over the joint, producing a robust, superior weld.

Digital control of current laser welding equipment via robotic interfaces or CNC systems allows for:

- Extremely great accuracy and consistency

- Intricate welding routes in three dimensions

- Real-time parameter modifications according to joint and material requirements

In industries like automotive, aerospace, electronics, and medical device manufacturing, machines like Laser Technologies India's Fiber Laser Welding Solutions are essential because they can handle a variety of materials, from strong structural metals to ultra-thin metals and delicate alloys.

2. Core Components of a Laser Welding Machine

A laser welding machine combines a number of complex subsystems, all of which are essential to precise, effective, and seamless welding processes. Let's dissect these essential elements and recognize each one's unique role in the welding process:

- Laser Source

- Lasers made of fiber: Nowadays, they are most frequently utilized because of their great beam quality, high efficiency, and small size.

- CO₂ Lasers: These older lasers are usually employed with legacy systems or non-metallic materials.

- Disk and diode lasers are a new technology that offers stability and targeted energy delivery for certain industrial applications.

- System of Beam Delivery

- Fiber optic cables that preserve beam quality over extended distances (for fiber lasers).

- Mirrors and lenses that accurately reflect and steer the beam (for CO₂ lasers).

- Focusing Optics

- For thick materials, deep penetration (keyhole mode) is used.

- Conduction mode surface-level welding for delicate and thin materials.

- Welding Head / Nozzle

- Insulating the molten pool from air pollution by directing shielding gases (argon, nitrogen, and helium).

- Preserving beam alignment and focus distance.

- CNC or Robotic Controller

- Pulse control, modulation, and laser power.

- Welding speeds and patterns.

- Workholding System

- Make sure it is consistent and repeatable.

- Avoid misalignment and material movement when welding.

- Shielding Gas Supply

- Make sure the weld pool is covered.

- Enhance the integrity and look of the weld.

- When welding at fast speeds, stabilize the arc.

- Chiller Cooling System

- Controls the temperature of important parts.

- Keeps the system from overheating and guarantees steady functioning.

- Safety Enclosures and Sensors

- Enclosures that protect operators from radiation.

- Interlock sensors that detect when doors or covers are opened to halt operations.

- Stop systems for emergencies and fault alerts.

This is the main component of the equipment, producing the laser beam that actually does the welding. Various laser sources have varying capacities:

The depth of penetration, weld speed, and material compatibility are all influenced by the laser source choice.

The laser beam must move from its source to the substance after it has been created. This is overseen by:

The delivery mechanism guarantees that the beam will arrive at the weld zone with the least amount of distortion and energy loss.

Focusing optics increases the energy of the laser beam by concentrating it into a precise location. This makes it possible for:

Additionally, dynamic control over heat input and weld seam dimensions is made possible by adjustable focussing.

In addition to housing the optics, the welding head frequently incorporates shielding gas nozzles. Its features include:

The welding head is where a steady and ideal weld environment begins.

This is the laser welding machine's brain. Beam route and location (2D or 3D movements) are controlled by the controller.

Robotic controllers coordinate motions with conveyors, part loading systems, and other devices for automated production.

The workpieces are kept correctly aligned during welding by fixtures and clamping systems. These systems:

Shielding gases are a crucial element in preventing oxidation and porosity.

Heat is produced during operation by laser sources and optics. The cooling mechanism:

Laser welding uses powerful beams that can be dangerous. Systems of safety consist of:

These parts work together to provide modern laser welding machines with their structural integrity and enable them to provide accurate, effective, and secure welding solutions for a variety of sectors.

3.The Procedure for Laser Welding: Step by step

The process of laser welding, which turns raw materials into precisely welded components, is meticulously regulated and mechanized. Every stage is essential to guaranteeing weld quality, efficiency, and repeatability, particularly in high-demand production settings like electronics, automotive, and aerospace manufacture.

Step 1 → The first step is to load and position the workpiece.

- To guarantee precision and consistency, the procedure begins with the workpieces being firmly clamped into place using fixtures and jigs.

- Because laser welding necessitates precise joint tolerances for successful fusion, workpieces must be appropriately cleaned and aligned.

- Welding settings and movement patterns are programmed into CNC controllers or robotic systems to ensure uniformity during several manufacturing cycles.

Step 2 → Laser Beam Initiation

- A high-intensity beam is emitted by the activated laser source and transmitted via fiber optics (for fiber lasers) or mirrors (for CO₂ lasers).

- Through the use of lenses, this beam is concentrated into a very small area, creating an energy density that is sufficient to melt the workpiece material at the joint

- In order to screen the molten pool from atmospheric gases like oxygen and nitrogen, which might cause porosity or oxidation flaws, shielding gas (argon, helium, or nitrogen) starts to flow simultaneously.

Step 3 → The Welding Phase, or Melting the Material

- The material's surface is quickly heated by the concentrated laser beam, reaching its melting point in a matter of milliseconds.

- Two types of welding take place, depending on the power density and travel speed:

- Conduction Mode: For thin materials with little depth, surface melting.

- Keyhole Mode: A deep, narrow hollow is created via deep penetration welding via vaporization.

- Both workpieces' molten material mixes in the weld pool, guaranteeing metallurgical bonding when it solidifies.

Step 4 → Completion and Solidification

- The molten pool rapidly cools and hardens as the laser beam moves along the weld path, creating a continuous weld seam.

- The risk of cracking, residual stress, or warping is reduced when laser power and travel speed are properly controlled to provide uniform cooling.

- During the welding process, high-precision equipment may dynamically modify beam focus and energy output to account for changes in material thickness or joint shape.

Step 5 → Cooling and Quality Inspection

- After the weld is complete, the component cools naturally or with the assistance of airflow or cooling systems.

- Quality inspection follows immediately, using visual checks, automated machine vision systems, or destructive/non-destructive testing methods (such as ultrasonic, dye penetrant, or X-ray testing) depending on industry requirements.

Advanced laser welding machines like the GH Series Fiber Laser Welders by Laser Technologies India combine automated part handling, smart welding parameter adjustments, and integrated quality assurance for fast, high-volume production without compromising weld quality.

Laser Welding Modes Supported by the Machine

Due to its ability to support many welding modes that are appropriate for various materials, joint types, and quality standards, laser welding machines are extremely adaptable. To choose the best parameters and get the required weld quality, it is crucial to comprehend these modes.

Mode of Conduction

Conduction mode works at lower laser power densities, when the material's surface is melted by the laser beam's heat without any deep penetration. Rather, a shallow weld is produced by the heat passing through the material.

Features:- shallow depth of weld

- visually beautiful, smooth weld seam

- Minimal thermal distortion

- Thin foils and sheets

- Materials that are sensitive to heat

- Applications like electronics and medical equipment that call for precise, surface-level joining

Keyhole Mode

At greater laser power densities, where the heat intensity is sufficient to form a tiny vapor cavity (keyhole) in the material, keyhole mode is triggered. As a result, the laser beam can enter the workpiece deeply.

Features include:- Narrow, deep welds.

- Weld seams with a high aspect ratio.

- Rapid welding speeds.

- Thick substances.

- Load-bearing and structural elements.

- Parts for automobile chassis and structural elements for aircraft.

🔹 Pulsed Mode

With pulsed laser welding, energy is delivered in brief, controlled bursts by rapidly turning the laser beam on and off. The heat input can be precisely controlled in this mode.

Qualities:- Reduces heat accumulation

- Lowers the chance of thermal damage and warping

- Outstanding control for applications involving microwelding

- Materials that are thin and sensitive to heat

- Jewelry, microelectronics, and stents are examples of precision components.

🔹 Mode Hybrid (Optional)

Laser welding and traditional arc welding techniques (such MIG or TIG) are combined in hybrid laser welding. This method makes use of the laser's deep penetration and arc welding's capacity to bridge gaps.

Features:- Increased ability to tolerate misalignment and joint gaps

- Enhanced strength and quality of the weld

- Reduced vulnerability to welding flaws

- Heavy fabrication sectors such as construction and shipbuilding

- Welding thick, massive plates

- Conditions in which fit-up is not optimal

The ability to vary between different welding modes according to part design, material thickness, and production requirements is provided by machines such as those sold by Laser Technologies India. This ensures maximum efficiency and versatility for a variety of industrial applications.

5. Automation and Smart Control

Modern laser welding equipment are made to easily interface with cutting-edge automation technologies as the manufacturing sector strives for increased productivity, efficiency, and uniformity. Through automation and intelligent control, laser welding is transformed from a manual or partially automated process into a fully automated manufacturing system that requires little human interaction and can run around the clock.

Combining 3D welding with robotics

Multi-axis robotic arms can be used with modern laser welding machines to enable welding in a variety of planes and orientations. This is especially crucial for intricate parts in the heavy machinery, automotive, and aerospace sectors, where weld seams might not necessarily follow straight or flat courses.

Benefits:- Makes it possible to fuse complex, three-dimensional components

- Decreases the need for manual work and improves repeatability and consistency

Management of CNC Systems and Part Programs

CNC controllers are used to operate laser welding machines, enabling pre-programming of laser settings, speeds, and weld routes. CNC control guarantees:

- Consistency between production batches.

- Simple transitions between product designs.

- Precise, quick, and error-free welding head movement.

🔹 Integration of MES and IoT

In order to allow smart factory capabilities, next-generation laser welding systems can interface to MES (Manufacturing Execution Systems) and IoT platforms. This offers:

- Data analytics and real-time production tracking.

- Alerts for preventive maintenance.

- For a smooth process, integration with enterprise resource planning (ERP) systems.

Adaptive welding and controllers powered by AI

Laser welding technologies are rapidly incorporating machine learning and artificial intelligence. AI-powered controllers are able to:

- Adapt laser power, speed, and focus distance automatically in response to variations in the material or irregularities in the joints.

- Real-time weld quality monitoring with sensors and cameras.

- Take remedial measures during the welding process to minimize flaws.

Other Insightful Features

- Seam tracking compensates for part movement or misalignment by automatically following the seam.

- Adaptive Power Control: Maintains weld quality by dynamically adjusting power.

- Defect Detection & Alerts: Can halt the operation or notify operators of problems like porosity, splatter, or gaps.

For sectors like electronics, automotive, and aerospace where volume, accuracy, and speed are all equally vital, smart control and automation make laser welding a highly scalable, predictable, and efficient process.

6. Summary of Advantages

| Feature | Laser Welding Machine Benefits |

|---|---|

| Speed | High-speed joining without pre/post-processing |

| Precision | Micron-level control over weld width and depth |

| Flexibility | Weld thin sheets to thick plates, metals to alloys |

| Clean Process | No electrode wear or filler metal required |

| Automation Ready | Automation Ready Integrates with robots, conveyors, smart factory solutions |

Conclusion

A laser welding machine combines motion control, optics, process intelligence, and a laser source in a complex way. while combined, they allow for the highest levels of accuracy, consistency, and speed while welding the complex pieces and modern materials of today.

Laser welding devices have become essential to industries looking for perfect welds with little downtime, including electronics, automotive, and aerospace.

Modern fiber laser welding solutions from Laser Technologies India have all of these characteristics, enabling companies to confidently automate and expand their manufacturing.

To find out how laser welding machines may revolutionize your manufacturing lines, get in contact with us right now.

"Types of Laser Welding (Fiber, CO₂, Hybrid, Ultrafast)" is the next task at Laser Welding University.