11. How to Maintain & Troubleshoot a Laser Welding Machine

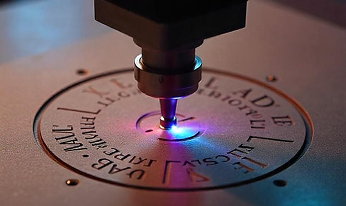

Introduction

Although laser welding machines are designed to be highly effective, precise, and long-lasting, they need routine maintenance and care, just like any other piece of industrial equipment, to guarantee their best performance and lifetime. Furthermore, knowing how to diagnose common problems can assist save downtime and prevent expensive repairs.

The best practices for maintaining your laser welding machine, typical issues you may encounter, and efficient troubleshooting techniques are all covered in this guide.

1 Importance of Regular Maintenance

Proactive maintenance ensures:

- Reliable weld quality

- Decreased chance of a machine malfunction

- Increased longevity of the machine

- Reduced operating expenses and downtime

Ignoring maintenance can result in subpar welds, broken parts, and unforeseen malfunctions that can cause delays in production.

Principal Advantages of Maintenance:

- Increased productivity and uptime.

- Less need for part replacements.

- Safeguarding expensive parts like lasers and optics.

2 Routine Maintenance Checklist

Every Day/Each Shift

- Visually check the machine for damage, dust, and filth.

- Examine every door and safety interlock.

- Make that the pressure and flow of the shielding gas are within the advised ranges.

Every week

- Use the appropriate lens wipes and chemicals to clean the optics.

- Examine and clean the laser head and nozzles.

- Check the chiller levels, and look for leaks in the hoses.

Monthly

- Check fiber delivery cables for damage or bends.

- Verify and tighten mounting points and mechanical fasteners.

- Update the firmware and software as necessary.

Quarterly/Annually

- Complete system alignment and calibration should be done.

- Replace any worn-out consumables, such as nozzles, mirrors, and lenses.

- Annual professional servicing is advised.

✅ By following this checklist, you may increase your laser's lifespan and guarantee dependable, superior welding.

3 Common Laser Welding Machine Issues & Troubleshooting

Inconsistent Weld Quality

Potential Reasons:

- The beam quality is reduced by dirty optics.

- The focus position is incorrect.

- Poor flow or contamination of shielding gas.

Solutions:

- Clean mirrors and lenses.

- Make sure the nozzle distance is appropriate and adjust the focus.

- Verify gas lines and swap out cylinders if necessary.

Machine Not Starting / Laser Not Firing

Potential Reasons:

- Systems of interlocks open.

- Issues with the cooling system.

- Problems with the power supply.

Solutions:

- Verify that all doors and covers are closed and that the safety circuits are turned on.

- Check coolant levels and the condition of the chiller.

- Verify the emergency stops and main power.

Excessive Spatter or Porosity

Potential Reasons:

- The wrong shielding gas.

- Unclean work surfaces or coatings of materials.

- Insufficient force or speed of travel.

Solutions:

- Verify the proper shielding gas and flow.

- Thoroughly clean the workpiece.

- Modify the welding parameters (speed, power).

Beam Alignment or Focus Issues

Potential Reasons:

- Optic movement during procedure

- Inadequate configuration or unintentional bumps

Solutions:

- Possible solutions include optical alignment.

- Use the auto-focus feature or recalibrate by hand.

Frequent troubleshooting helps stop minor problems from growing into significant machine failures.

4 Preventive Maintenance Programs (PMP)

Preventive Maintenance Contracts (PMCs) are provided by numerous manufacturers, such as Laser Technologies India, to:

- Conduct expert-level maintenance and inspections.

- Provide approved accessories and parts.

- Make sure the firmware and software are always up to date.

- Teach operators the best methods for maintenance.

For PMPs, collaborating with your machine provider guarantees stress-free machine maintenance and peak performance.

Conclusion

Laser welding devices require discipline, care, and attention in routine maintenance, just like any other precise equipment. Knowing how to properly maintain and troubleshoot your computer can allow you to:

- Reduce the amount of unplanned downtime.

- Boost the quality and consistency of the weld.

- Increase the investment's longevity.

- Reduced operational expenses over the long run.

In order to keep your laser welding operations productive, effective, and seamless year after year, Laser Technologies India provides thorough service, maintenance, and troubleshooting support.

"Best Software for Laser Welding Machine Operation" is the next event at Laser Welding University.