4.0 Materials Suitable for Laser Welding

Introduction

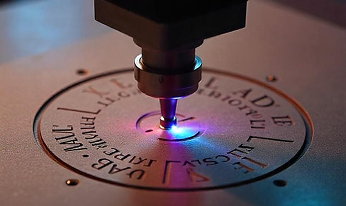

Laser welding is a popular option in a variety of industries, including electronics, automotive, aerospace, and medicine, since it provides exceptional precision, speed, and versatility. But not every material is a good fit for laser welding. To attain ideal welding performance, prevent flaws, and increase production, it is crucial to comprehend which materials react best and why.

This guide covers:

- The kinds of materials that are most suited for laser welding.

- How they weld.

- Particular attention to every material group

- Some pointers for enhancing weldability.

1. Metals Suitable for Laser Welding

Carbon Steel (Mild and Low Alloy Steels)

- Superior weldability when using fiber lasers.

- Deep penetration is feasible with few flaws.

- Ideal for general manufacturing, structural, and automotive applications.

Considerations:

- To avoid cracking, thicker portions or high-carbon varieties may need to be preheated.

Stainless Steel (Austenitic, Ferritic, Martensitic)

- High absorptivity results in excellent laser weldability.

- Creates robust welds that are resistant to corrosion.

- Extensively utilized in the food, chemical, medical, and architectural sectors.

Considerations:

- A proper shielding gas, such as nitrogen or argon, is necessary to prevent porosity and oxidation.

Aluminum and Aluminum Alloys

- Moderate weldability (lower initial beam absorption due to increased reflectivity).

- Fiber lasers are capable of welding thin to moderately thick materials with efficiency.

- Widely utilized in electronics, airplanes, and automobiles (lightweight constructions).

Considerations:

- Higher power and beam control are needed for high reflectivity and heat conductivity.

- The choice of shielding gas must be carefully considered.

Titanium and Titanium Alloys

- Superior weldability.

- Creates joints that are extremely robust, corrosion-resistant, and clean.

- Frequently used in military, medical implants, and aerospace.

Considerations:

- Requires inert gas shielding to avoid contamination and breakdown.

Nickel and Nickel Alloys (Inconel, Monel)

- Deep penetration and good weldability.

- Keeps its mechanical qualities after welding.

- Utilized in power generating, chemical processing, and aerospace.

Considerations:

- To prevent cracking, exact control of heat input is necessary.

Copper and Copper Alloys (Brass, Bronze)

- Traditionally difficult because of high reflectivity.

- Copper welding is now possible thanks to high-power fiber lasers or green and blue lasers.

- Vital for heat exchangers, electrical connectors, and EV batteries.

Considerations:

- Requires specific laser wavelengths or extremely high peak power.

2. Non-Metallic Materials Suitable for Laser Welding

Plastics (Thermoplastics)

- Transparent and absorbent polymers are used in laser transmission welding.

- Accurate, clean weld joints free of fasteners or adhesives.

- Frequently found in consumer goods, medical equipment, and car interiors.

Considerations:

- Materials must be laser transparent or absorb at the laser wavelength, among other considerations.

- To guarantee intimate contact, proper clamping is required.

Glass and Ceramics

- Ultrafast lasers allow fragile materials to be welded without cracking.

- Utilized in specialized applications, electronics, and optics.

Considerations:

- For great precision, femtosecond lasers are needed.

- Limited flexibility in joint design.

3. Factors That Influence Weldability

- Thermal conductivity and material thickness: :Faster welding speeds and more power are needed for high conductivity metals.

- Reflectivity:Special laser sources or beam modification may be required for reflective materials such as copper and aluminum.

- Laser wavelength absorptivity: Establishes melting efficiency and initial energy absorption.

- Shielding requirements:In order to stop oxidation, reactive materials like titanium and stainless steel require inert shielding gases.

- Joint design and fit-up: For flawless welding, precise tolerances and spotless surfaces are crucial.

Conclusion

Anything from conventional steels and aluminum to contemporary alloys, copper, polymers, and even glass can be welded using laser technology. The correct laser type selection, knowledge of material properties, and precise process parameter control are crucial for success.

- Excellent laser weldability is provided by metals such as mild steel, titanium, nickel alloys, and stainless steel.

- Modern fiber and ultrafast lasers have made it possible to weld more difficult materials like copper and aluminum.

- Although they need specific methods, non-metals like glass and polymers are becoming more and more common in laser welding application

Our fiber, hybrid, and ultrafast laser welding technologies at Laser Technologies India are designed to accurately and dependably handle this wide range of materials.