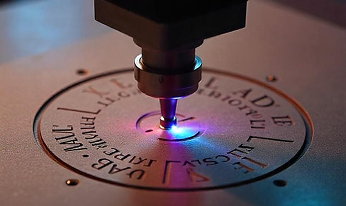

6.0 Understanding Laser Welding Parameters (Power, Speed, Focus, Shielding Gas)

Introduction

In laser welding, having the correct machine is not enough to produce perfect, high-quality welds. Understanding the crucial process variables that govern the welding dynamics is the real secret. A robust, flawless weld that satisfies the exact requirements of a variety of industries, from electronics and medical to automotive and aerospace, is ensured by properly adjusting parameters including power, speed, focus, and shielding gas.

To attain the finest outcomes in laser welding, we will dive deeply into these crucial parameters, their functions, their interactions, and best practices in this book.

1. Laser Power

- Laser Power: What Is It?

Laser power, which is commonly expressed in watts (W) or kilowatts (kW), is the quantity of energy that the laser beam delivers per unit of time. - Power's function in welding penetration depth: Greater power results in deeper weld penetration.

- Welding speed: Without sacrificing weld quality, more power enables faster travel speeds.

- Material compatibility: To guarantee correct fusing, different materials and thicknesses call for different power levels.

- Top Techniques:

- To avoid burn-through or excessive HAZ, avoid becoming overwhelming.

- For precision applications and thin materials, use less power.

The fiber laser welding systems from Laser Technologies India provide accurate power management to handle thick industrial materials and thin sheets.

2. Welding Speed

- What is Welding Speed?

Usually expressed in mm/sec or m/min, welding speed is the velocity at which the laser beam travels along the joint. - Speed’s role in welding:

- Speed's function in welding heat input control Increased speed lowers HAZ and heat input.

- Weld quality: Undercutting, porosity, and excessive spatter are avoided at the right speed.

- Productivity: Throughput and efficiency are increased by optimized speed.

- Top Techniques:

- Achieve flawless welds by striking a balance between power and speed.

- For deeper penetration and thicker materials, use slower speeds.

- Thin metals and the conduction mode benefit from higher speeds.

3. Focus Position

- What is Focus Position?

The distance between the workpiece surface and the laser's focal point is referred to as focus. It is possible to set this:- Surface-wise (zero focus)

- The surface level (positive focus)

- Negative focus, or under the surface

- Focus's Function in Welding:

- Control of penetration: Penetration is increased by negative focus (keyhole mode).

- Surface quality: Surface finish (conduction mode) is enhanced by positive or zero focus.

- Weld width: The width and depth of the weld bead are altered by changing the focus.

- Top Techniques:

- Use auto-focus heads to consistently maintain the best possible focus.

- For heavier materials, use a slightly negative focus to guarantee complete penetration.

- For precise welding on thin or delicate objects, use zero or positive focus.

4. Shielding Gas

- What is Shielding Gas?

Shielding gases are used to keep ambient gases like nitrogen and oxygen from contaminating the molten weld pool. - Common Shielding Gases and Their Roles:

- Argon: The most often utilized, it offers stable arc and good protection.

- Nitrogen:Enhances corrosion resistance in stainless steel.

- Because of its increased thermal conductivity, helium offers deeper penetration.

- Shielding Gas's Function in Welding:

- Stops pollution and oxidation.

- Enhances the surface quality and weld look.

- Minimizes spatter and stabilizes the welding process.

- Top Techniques:

- Make sure the flow rate is sufficient (too high causes turbulence; too low means pollution).

- Choose the gas according to the material and the desired weld characteristics.

5. The Interaction of Parameters

To get the best results, power, speed, focus, and shielding gas must all be carefully balanced. No parameter functions in isolation.

Sample Scenario

- Deep penetration with high power and slow pace, however there is a chance of distortion and overheating.

- Fast speed combined with low power means a clean weld but a chance of partial fusion.

- Inaccurate focus: Excessive spatter or poor penetration.

To ensure constant weld quality, particularly in automated production situations, these parameters must be fine-tuned.

Conclusion

To fully utilize this advanced joining technology, it is imperative to understand and manage laser welding parameters. In addition to guaranteeing exceptional weld strength and appearance, the right settings also increase output and lower rework.

- Heat input and penetration are determined by laser power.

- Heat distribution and weld quality are controlled by welding speed.

- Weld depth and bead form are affected by focus.

- Clean and flawless welds are guaranteed by shielding gas.

Manufacturers can produce predictable, high-performance outcomes across a variety of materials and applications by understanding these factors and how they interact.

Our intelligent laser welding systems atLaser Technologies India provide customers with easy access to precise control over all important parameters, enabling them to easily achieve world-class welding performance.

"Automation and AI in Laser Welding" is the next topic at Laser Welding University.