7.0 Automation and AI in Laser Welding

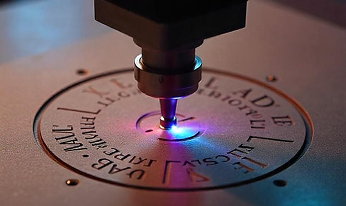

Introduction

Automation and artificial intelligence (AI) are turning laser welding into a highly intelligent, adaptable, and self-optimizing process as companies continue to adopt smarter, faster, and more efficient manufacturing techniques. Automation and artificial intelligence (AI) are redefining what is feasible in terms of accuracy, speed, and repeatability in a variety of industries, including electronics, medical devices, automotive, and aerospace.In this manual, we will look at:

- Automation's function in laser welding.

- How welding systems are incorporating AI.

- Principal advantages and applications.

- New developments and prospects for smart laser welding.

1. The Role of Automation in Laser Welding

The capacity of laser welding to produce reliable, high-quality welds at extremely high speeds makes it an ideal choice for automation. Due to its precision-based and non-contact operation, laser welding eliminates many of the human factors that were previously required by welding methods like MIG or TIG.

In addition to boosting efficiency, automation in laser welding guarantees improved precision, consistency, and security. For industries with high production demands, it decreases operator fatigue, lowers errors, and permits round-the-clock work.

Why Automation is Ideal for Laser Welding

- Non-contact process:It is simple to automate because there is no electrode wear or need for manual torch handling.

- High welding speeds: Automation is more economical because it is quicker than traditional welding.

- Precision and repeatability::Across thousands of parts, robotics and CNC systems guarantee the same outcomes.

- Smooth integration with production lines:Robotic arms, turntables, and conveyors can all be equipped with laser welding systems.

-

Types of Automated Laser Welding Systems:

- In the automotive and aerospace industries, robotic welding cells allow for multi-axis movement for intricate weld geometries.

- Cartesian and gantry systems are ideal for uniform, straight weld seams on big flat panels.

- Conveyor Integrated Systems: Perfect for high-volume manufacturing, including assembling small parts or consumer electronics.

- Indexing systems and rotary tables are utilized in small-batch manufacturing or when several components need to be welded one after the other.

Advantages of Laser Welding Automation:

- Greatly cuts labor expenses and production time.

- Reduces heat and fume exposure, improving worker safety.

- Ensures dependable and constant weld quality.

- Makes it easier to integrate Industry 4.0 technology and digital manufacturing environments.

From small robotic cells to fully automated production lines tailored to the requirements of the automotive, appliance, aerospace, and industrial sectors, Laser Technologies India offers end-to-end automated laser welding solutions.

2. Introduction of AI in Laser Welding

By converting conventional automated systems into intelligent, adaptable processes that can make decisions in real time, artificial intelligence (AI) and machine learning are completely changing laser welding. AI-powered laser welding machines evaluate incoming data, learn from patterns, and dynamically modify parameters to maintain weld quality and uniformity without the need for human interaction, in contrast to simple automated systems that rely on pre-programmed settings.

The Need for AI in Laser Welding

- Variations in Material and Joint Conditions: Not all weld joints are flawless in actual manufacturing. AI facilitates adaptation to anomalies such as surface pollution, inconsistent materials, or misaligned parts.

- Quality Assurance: Welding flaws can be immediately identified by utilizing AI-powered image processing and sensor data. By doing this, fewer faulty items make it to the following stages of production.

- Process Optimization: By continuously enhancing weld schedules and settings through the analysis of historical welding data, AI algorithms raise first-pass yield rates.

AI Integration Capabilities:

- Process Monitoring in Real Time Critical weld properties like melt pool form, keyhole dynamics, and plume behavior are tracked by sophisticated sensors and cameras. In order to identify problems like unstable keyholes, splatter, or inadequate penetration, AI systems rapidly process this data.

- Adjustments to Predictive Parameters AI systems automatically modify critical parameters like laser power, welding speed, and focus location to stabilize the process when anomalies are identified.

- Automated Inspection of Quality AI-powered vision systems check finished weld seams for flaws including undercutting, fractures, and porosity. Welds are categorized as pass or fail by AI algorithms, which eliminates the need for manual inspection and increases manufacturing efficiency.

- Self-Education and Enhancement AI algorithms optimize future weld settings by continuously learning from production data. The system gradually optimizes welding schedules to lower cost per part, cycle time, and energy consumption.

Even in fluctuating production situations, this predictive control ensures consistent weld quality by reducing downtime and rework.

AI-powered laser welding aims to create intelligent, self-adapting manufacturing lines that can maximize output and quality without the need for human involvement. It is no longer only about automation.

3. Use Cases and Applications

Laser welding is proven to be an invaluable tool for a variety of industries that require accuracy, consistency, and productivity—especially when combined with automation and artificial intelligence.

Automotive Industry

One of the largest markets for automated laser welding technologies is the automotive industry.

From battery cells to structural elements, laser welding assures:

Body-in-White (BIW) Assembly: Robots with laser welding heads quickly and consistently attach massive

body panels with beautiful weld quality.

EV Battery Welding: AI-assisted laser welding is essential for enclosures and battery tab connections, where

accuracy and heat control are essential for functionality and safety

Powertrain and Gear Components: Reliability in crucial drivetrain components is

ensured by deep penetration and low distortion.

Aerospace Industry

To guarantee safety and structural integrity, aerospace welding requires

precise tolerances and flawless welds:

Lightweight Alloy and Titanium Welding: Laser welding allows for the distortion-free

joining of materials that are challenging to weld.

Important Structural Elements: AI-powered real-time process monitoring guarantees

flawless welding on components subjected to high stress.

Fuel and Hydraulic Systems: The short HAZ of laser welding reduces

the possibility of contamination and increases longevity.

Electronics Manufacturing

Micro-precision and clean welds without destroying delicate components are necessary in the

production of electronics:

Sensor and connector microwelding: Lasers attach small parts without damaging

neighboring components by supplying regulated, localized heat input.

AI-driven Inspection: In high-volume manufacturing, automated flaw detection guarantees reproducible quality.

Medical Device Manufacturing

Ultra-clean, accurate welds with complete traceability are required by the medical sector:

Implants and surgical instruments: Laser welding reduces the need for post-processing by

producing strong, smooth, and biocompatible welds.

Sterile Production with AI Monitoring: Strict adherence to medical standards and flawless

production are guaranteed by real-time process control.

Leading users of AI-driven, automated laser welding systems are these sectors, where accuracy, traceability, and zero-defect manufacturing are essential. In addition to addressing today's production issues, the technology opens the door for future factories that are smarter and more productive.

4.Future Trends and Innovations

Rapid advances in technology in the laser welding business are changing production tactics across industries as automation and artificial intelligence continue to advance. In addition to improving accuracy and efficiency, these developments are making laser welding a more flexible and self-sufficient procedure.

Closed-loop AI-Powered Systems:

Autonomous Control: Thanks to real-time data from sensors and vision systems, sophisticated AI algorithms

can now modify welding parameters like power, speed, and focus in real-time.

Self-Optimization: By automatically optimizing weld performance from massive volumes of historical

and real-time data, these technologies lessen human reliance and guarantee constant quality.

Reduced Defects: By rapidly adjusting to changing production conditions and material discrepancies,

closed loop systems dramatically reduce the chance of defects.

Cloud-Connected Welding Ecosystems:

Centralized Data Management: Manufacturers can track and examine welding

activities in several locations thanks to cloud-connected solutions that gather and

store production data in real time.

Predictive maintenance reduces unscheduled downtime by using AI to evaluate cloud data, forecast

component failures, and proactively schedule repair.

Remote Monitoring and Support: By enabling engineers to access and control welding systems from a distance,

they can increase responsiveness while cutting labor and travel expenses.

AI combined with Collaborative Robots (Cobots):

Safe Human-Robot Interaction: In smaller or mixed-production settings, cobots with sophisticated

sensors and artificial intelligence (AI) can safely collaborate with human operators to increase automation capabilities.

Fast Deployment: AI makes it easier to program cobots, allowing for quick setup for novel welding

operations without requiring a lot of code or downtime.

Flexible Production: Cobots are perfect for small to medium-sized production runs where adaptability and switchover simplicity

are crucial.

Using AR and VR to Remotely Configure and Diagnose Issues:

AI-Enhanced Training: To help operators and maintenance personnel with setup and

troubleshooting, Augmented Reality (AR) technologies provide visual,

step-by-step instructions driven by AI.

Virtual Commissioning: By simulating and validating welding programs before they go online,

virtual reality (VR) settings can cut down on setup time and errors.

Remote Collaboration: By allowing off-site specialists to support and mentor on-site teams,

AR and VR minimize downtime and increase the effectiveness of problem-solving.

As these technologies develop, artificial intelligence (AI) and sophisticated automation will transform laser welding into an autonomous and self-learning production process that can be easily incorporated into Industry 4.0 settings and smart factories.

Conclusion

Advanced laser welding has made automation and artificial intelligence (AI) indispensable for increasing productivity, accuracy, and competitiveness. Manufacturers can use AI and intelligent automation to accomplish:

- Higher rates of output.

- Improved consistency and quality of the weld.

- Lower expenses and less rework.

- More intelligent, self-correcting welding techniques.

The ability of laser welding to learn, adapt, and optimize in real-time production situations is what will determine its future, from collaborative robots and predictive maintenance to robotic welding cells and adaptive AI control.

By incorporating automation and artificial intelligence (AI) into its laser welding solutions, Laser Technologies India assists enterprises in embracing Industry 4.0 and constructing the factories of the future.