5.0 Laser Welding Technologies — The Science Behind Laser Welding

Introduction

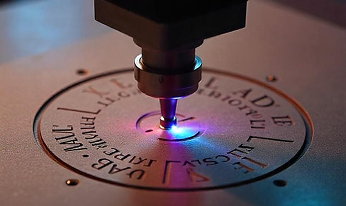

More than just a sophisticated joining technique, laser welding is an amazing fusion of technical accuracy, material science, and physics. Understanding the fundamental scientific concepts behind laser welding's operation is essential to maximizing its potential in sectors like automotive, aerospace, electronics, and medicine.

The principles of laser-material interaction, welding modes, beam characteristics, and the metallurgical science that makes laser welding the go-to option for precision joining applications are all broken down in this article

1. Laser-Material Interaction: The Foundation of Laser Welding

When the intense, concentrated laser beam hits the material surface, laser welding starts. The following is a perfectly balanced series of physical events:

- Absorption:

- At their surface, metals absorb a portion of the laser energy.

- The material type, surface condition, and laser wavelength all affect the absorption rate.

- High absorption in metals such as titanium and steel is possible using fiber lasers (wavelength ~1070 nm).

- Melting and Vaporization:

- The metal is heated above its melting point by the absorbed energy.

- Vaporization may happen as the temperature rises, particularly in keyhole mode.

- Plasma Formation (in keyhole mode):

- A plasma plume produced by vaporization can help or impede energy absorption.

- The plasma behavior of modern laser systems is stabilized for reliable welding.

- The process of solidification:

- The molten pool cools and hardens as the laser beam advances.

- This creates a solid junction that is metallurgically bonded.

For laser welding to produce flawless welds, control over absorption, heat input, and solidification is essential.

2. Laser Welding Modes: Conduction vs Keyhole vs Hybrid

- Mode of Conduction:

- Low density of energy (less than 10⁶ W/cm²).

- Heat is transferred into the surface of the substance

- Creates welds that are smooth, shallow, and visually appealing.

- Ideal for fragile components and thin materials.

- Keyhole Mode:

- High density of energy (>10 W/cm²).

- Vaporization produces a keyhole, which is a deep, narrow cavity.

- Permits fast, deep penetration welding.

- Used for structural elements and thicker portions.

- Hybrid Welding (Laser + Arc):

- Combines the gap-bridging capabilities of arc welding with the deep penetration of laser.

- Perfect for heavy machinery, automobile body construction, and shipbuildin

Switching between these modes provides versatility in terms of material thicknesses and types.

3. Laser Beam Properties and Their Impact on Welding

The properties of the laser beam are what mostly drive the special capabilities of laser welding:

- Power Density (W/cm²):

- The energy per unit area at the workpiece is defined by the power density (W/cm²).

- Establishes whether keyhole or conduction welding mode is used.

- Wavelength:

- Absorption efficiency depends on wavelength.

- Near-infrared fiber lasers work best on metals.

- Far-infrared CO₂ lasers work better on non-metals.

- Focus Spot Size:

- Greater precision and power density result from a smaller spot.

- Optimisation for penetration versus surface quality is possible with adjustable optics.

- Beam Quality (M² value):

- The laser's ability to focus firmly is determined by its beam quality (M² value).

- Improved beam quality results in deeper penetration and thinner weld seams.

Modern fiber lasers are ideal for a wide range of welding applications because they provide exceptional beam quality and power control.

4. Metallurgical Science in Laser Welding

High weld integrity requires an understanding of solidification dynamics and molten metal behavior.

- Heat Affected Zone (HAZ):

- The region surrounding the weld that is thermally changed but not melted is known as the Heat Affected Zone (HAZ).

- Compared to traditional welding, laser welding creates a much smaller HAZ.

- Solidification Rates:

- Fast cooling speeds enhance mechanical qualities and inhibit grain development.

- Cracking and porosity are prevented by proper control.

- Metallurgical Bonding:

- Strong joints are created when molten materials combine at the atomic level.

- If necessary, filler material can be added to further maximize composition and strength.

Laser welding is perfect for high-spec industries like aerospace and medicine because of its metallurgical precision.

Conclusion

Laser welding is a science that perfectly combines process control, material behavior, and physics. Manufacturers may realize the full potential of laser welding technologies by comprehending how metallurgical bonding occurs, how various welding modes operate, and how laser energy interacts with materials.

- Energy absorption and melting behavior are defined by the laser-material interaction.

- Welding modes provide thickness, speed, and appearance optimization.

- The accuracy and adaptability of the welding process are determined by the characteristics of the beam.

- Strong, flawless welds are ensured by metallurgical expertise.

Based on these scientific principles, Laser Technologies India's laser welding systems are designed to provide outstanding performance, dependability, and industry adaptability.

"Understanding Laser Welding Parameters (Power, Speed, Focus, Shielding Gas)" is the next topic covered at Laser Welding University.