1.0 What is Laser Welding? (Introduction & Basic Principles)

Introduction

The art and science of metal joining in precision manufacturing industries have been completely transformed by laser welding. From tiny, highly precise medical devices with incredibly fine weld seams to sturdy welds in heavy industries like aerospace and automotive, laser welding technology is now at the pinnacle of manufacturing. Today, laser welding is essential to the production of goods all over the world. We will go into great detail about the principles and technicalities of laser welding in this comprehensive guide:

- The definition of laser welding and its operation.

- The physics of laser welding.

- Important welding modes (Keyhole vs. Conduction).

- Laser types that are employed.

- Parameters for the process.

- Benefits and drawbacks.

- Applications in electronics, automotive, aerospace, and medicine.

- Innovations and prospects for the future.

What is Laser Welding?

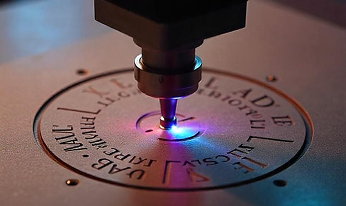

Laser welding is a fusion joining technique that melts and joins materials using a laser beam that is highly concentrated. The accuracy of laser beams enables producers to produce precise, robust, and clean welds without the need for filler material or physical contact in the majority of circumstances.

It is categorized as a high-precision, non-contact thermal process.

Essential qualities:- Concentrated energy density.

- Heating in a certain area.

- Fast processing.

- Thin and extensive weld penetration.

Although CO₂, disk, diode, and ultrafast lasers also play important roles depending on the application, fiber lasers are the most common type of laser utilized today.

Physics of Laser Welding: How It Works

The basic ideas of heat transport, energy absorption, and metallurgical transformation govern laser welding. To maximize weld quality and process stability, it is essential to comprehend these physical interactions.

Laser-Material InteractionWhen a concentrated laser beam hits a material's surface, a number of quick events take place.

- Absorption: Depending on its reflectivity and thermal characteristics, the surface absorbs laser energy. Although steels absorb well, metals like aluminum reflect more.

- Heating and Melting: A molten pool is created when the absorbed energy quickly raises the temperature above the material's melting point.

- Keyhole Mode Vaporization: At extremely high intensities, some material vaporizes, creating a "keyhole" that permits deeper penetration.

- Solidification: To create a solid metallurgical bond, the molten pool cools and solidifies as the laser continues to operate.

Heat Transfer Mechanisms

- Conduction:Heat transfers from the laser light onto the surrounding material while in conduction mode. This results in clean weld seams but limits weld depth.

- Convection and Vaporization: In keyhole mode, vapor pressure permits molten metal to flow and connect, transferring energy deeper.

Key Factors Influencing Laser Welding Physics

- Wavelength and Absorptivity:Compared to CO₂ lasers (~10.6 μm), fiber lasers (~1070 nm) exhibit improved metal absorption.

- Power density:It determines Conduction, transition, or keyhole mode activity.

- Beam Focus: Weld penetration and width are impacted by tight focusing, which raises energy density.

- Shielding Gas:Modifies cooling speeds, stabilizes the melt pool, and inhibits oxidation.

In order to achieve the best weld outcomes across a range of materials and thicknesses, advanced fiber laser systems provide exact control of key physical factors.

The fundamental physics concepts of energy transfer and material absorption are the foundation of laser welding.

- Optical energy is concentrated into a tiny area by laser beams.

- This energy is absorbed by material, which turns light into heat.

- A molten pool is produced when the heat locally melts the substance.

- The molten metal solidifies and creates a junction as soon as the laser advances.

Key physical factors:

- Absorption coefficient:Metals melt more effectively if they absorb more light at the laser wavelength.

- Thermal conductivity:Heat can remain confined when conductivity is low.

- Reflectivity:Higher power or pulse lasers are needed for reflective metals like copper and aluminum.

Laser Welding Modes: Conduction vs Keyhole vs Hybrid

Depending on the power density and the way the laser interacts with the material, laser welding allows a variety of welding modes rather than depending on a single heat input and fusion technique. Different materials and applications work best with each mode.

Welding in Conduction Mode

The laser beam's power density in conduction mode is comparatively modest, at less than 10 W/cm². Heat moves through the material as the laser energy is absorbed on the surface. This leads to:

- Welds with shallow penetration (0.1–0.5 mm).

- Beautiful and seamless weld seams.

- Less splatter and a lower chance of flaws.

The best uses for conduction mode are:

- Light sheets.

- Electronic or medical enclosures sealed with hermetic.

- Heat-sensitive materials being welded.

Keyhole Mode Welding

The laser beam is significantly stronger in keyhole mode, surpassing 10⁶ W/cm². As a result, vaporization occurs locally, forming a small vapor cavity known as a "keyhole."

- Permits welds with deep penetration (up to 25 mm).

- Permits rapid welding speeds.

- Produces narrow, robust weld seams.

Common applications for keyhole welding include:

- Welding thick plates.

- Structures used in automobiles and aircraft.

- Robotic welding cells with high speed.

Hybrid Laser Welding

Laser welding and traditional arc welding techniques (such MIG or TIG) are combined in hybrid laser welding. There are various benefits to this synergistic approach:

- Deep penetration from the laser beam combined with arc welding's ability to bridge gaps.

- Greater adaptability to changes in joint fit-up.

- Better quality welds on heavier materials.

The best uses for hybrid welding are:

- Building Ships.

- Steel fabrication and large-scale construction.

- Production of automotive body-in-white (structural vehicle parts).

Fiber laser systems from Laser Technologies India are compatible with hybrid welding solutions for more difficult production settings and can switch between conduction and keyhole modes with ease.

Welding in Conduction Mode:

- Low density of power (less than 10 W/cm²).

- Heat moves through the surface of the workpiece.

- Penetration that is shallow (0.1–0.5 mm).

- Perfect for hermetic sealing and thin sheets.

Welding in Keyhole Mode:

- High density of electricity (> 10⁶ W/cm²).

- A "keyhole" or cavity is created by vaporized material.

- Penetration depth of up to 25 mm.

- Utilized for structural components and heavy materials.

Laser welding that is hybrid:

- Combining arc and laser welding (e.g., MIG, TIG).

- Advantages of filler metal flexibility and deep penetration.

- Perfect for building ships and big constructions.

Laser Technologies India's fiber laser systems enable power and focus-based adjustment between conduction and keyhole modes.

Types of Lasers Used in Welding

| Laser Type | Power Range | Typical Application |

|---|---|---|

| Fiber Laser | 500W–30kW | Automotive, aerospace |

| CO₂ Laser | 100W–10kW | Plastics, non-metals |

| Diode Laser | 50W–5kW | Thin sheet metal, plastics |

| Disk Laser | 500W–16kW | Automotive, aerospace |

| Ultrafast Lasers | <100W | Medical devices, micro-welding |

Modern production is dominated by fiber lasers for the following reasons:

- Small size

- Low maintenance

- High (up to 50%) electrical efficiency.

- Delivery of flexible beams

Key Process Parameters

Power of the Laser:

- Regulates the depth and speed of penetration.

- Deeper welds with higher power.

Welding Speed

- Shallower welds result at higher speeds.

- Slow pace results in thin, deep welds.

Focus Point

- Focus point influences bead form and heat input.

- Surface polish versus penetration is controlled by positive/negative offsets.

Argon, helium, and nitrogen shielding gases

- Prevent oxidation of the molten pool.

- Enhances penetration and stabilizes the arc.

For Pulsed Laser Welding (pulse frequency)

- Used in heat-sensitive materials and microwelding.

For repeatable, optimal welds, Laser Technologies India offers welding solutions with intelligent parameter settings.

Advantages of Laser Welding

- Precision:Micron-level regulation of heat input and weld seam size.

- Speed: very quick in contrast to conventional arc welding.

- Minimal Heat-Affected Zone: Reduced post-processing and distortion.

- Clean Welding:Usually, no filler material or electrode wear is needed.

- Automation-Friendly: combining robotics and CNC to produce large quantities.

Comparison with Traditional Welding

| Feature | Traditional Arc Welding | Laser Welding |

|---|---|---|

| Heat Input | High | Low |

| Weld Size | Large | Small/Precise |

| Speed | Moderate | Very High |

| Automation | Difficult | Easy |

| Material Types | Limited | Broad |

Limitations of Laser Welding

- High Initial Investment: The initial cost of advanced laser systems is higher.

- Reflective Materials:Need sophisticated lasers or modifications to the method.

- Joint Preparation: A precise fit-up is required; gap tolerance is strict.

- Safety Precautions: Control measures are necessary for laser radiation and fumes.

Applications Across Industries

In many industries where accuracy, strength, and speed are crucial, laser welding has quickly become indispensable. Let's take a closer look at each industry to see how laser welding is changing it.

- Automotive Industry:

To increase performance and fuel efficiency, modern cars need lightweight structures, cutting-edge materials, and precise couplings. Laser welding finds extensive application in:

- Body-in-white assembly: Using high-speed, automated equipment, laser welding joins pillars, doors, and roof panels to produce visually appealing, clean welds without the need for grinding.

- Powertrain components: Keyhole laser welding can produce the deep, robust welds needed for engine, clutch, and transmission gear components.

- EV battery modules: Low heat input ensures electrical conductivity while preventing damage to delicate cells, making laser welding essential for joining battery tabs and housings.

- Heat shields and exhaust systems: To reduce deformation and preserve attractiveness, thin sheets of stainless steel are welded in conduction mode.

- Aerospace Industry:

The highest degree of precision as well as reliability are required in aerospace. In this area, laser welding is excellent:

- Structural components: For fuselage sections, wing assemblies, and engine parts, deep penetration keyhole welding is used to combine lightweight, high-strength materials like titanium and Inconel.

- Fuel system components: In aircraft, leak-proof and corrosion-resistant welds are crucial. By ensuring low HAZ, laser welding avoids structural flaws.

- Engine mounts and turbine blades: Robotic laser welding systems provide precise welds at challenging angles and locations.

- Medical Devices Industry:

Clean, accurate, and biocompatible joints are essential for medical components. These exacting specifications are easily satisfied by laser welding:

- Orthopedic and dental implants: Long-term dependability and patient safety are guaranteed by the contamination-free laser welding of titanium plates, rods, and implants.

- Surgical instruments: Conduction mode is used to combine stainless steel scissors, forceps, and micro-instruments with smooth, burr-free welds.

- Stents and micro-devices: To prevent heat damage, pulsed and ultrafast lasers are used to weld ultra-fine wires and meshes for vascular implants.

- Electronics Industry:

Electronics miniaturization requires the careful assembly of tiny, delicate components. Unmatched heat control and precision are provided by laser welding:

- Battery packs and tabs: Reliability of batteries in EVs and mobile devices is ensured by conductive, long-lasting welding with minimal heat impact.

- Sensors and micro-connectors: Laser welding makes it possible to link delicate parts without coming into contact with one another and without causing internal circuit damage.

- Mobile phones and wearable technology: Sturdy, beautiful welds enhance the look and longevity of products.

Laser welding is crucial for guaranteeing resilience without sacrificing design as electronics get smaller and more feature-rich.

- Emerging Industries and Applications:

- Shipbuilding: For big constructions, hybrid laser welding combines the gap tolerance of arc welding with the depth of laser welding.

- Energy (solar, wind): Heat exchanger and turbine parts made of high-strength welds.

- Luxury goods and jewelry: expertly welded precious metals without sacrificing aesthetic appeal.

The requirement for lightweight metals and small assemblies brought about by the automobile industry's transition to electric vehicles has increased demand for laser welding even more.

Laser welding is essential for crucial aerospace assemblies because of its non-contact nature and capacity to yield reliable, repeatable outcomes.

In cleanroom production, laser welding is essential for creating sterile, flawless medical items.

Laser Technology India's fiber laser welding systems are trusted because of their adaptability, accuracy, and integration potential, which enables producers to satisfy current production demands. It is also trusted for automotive body shops and precision medical part fabrication.

Innovations and Future Outlook

Emerging technologies and the rising need for precision manufacturing in cutting-edge industries are driving the rapid evolution of laser welding. Although it is already widely used in sectors including electronics, automotive, aerospace, and medicine, a number of developments are expected to expand its potential.

Real-Time Monitoring and Closed-Loop Control

Advanced sensors, cameras, and artificial intelligence algorithms are now being added to modern laser welding machines to allow for real-time welding process monitoring. This guarantees:

- Defects are detected immediately (porosity, cracks, gaps).

- Instantaneous focus, speed, and laser power adjustments.

- Enhanced quality assurance and traceability. This method guarantees increased yield and dependability in sectors where zero-defect manufacturing is essential, such as aerospace and medicine.

AI and Machine Learning-Powered Welding

Machine learning based laser welding system can learn from historical welding data and adjust parameters on-the-fly according to materials and joint geometry. Benefits include:

- Reliable quality of even difficult substance.

- Parameter setting and process optimization is automatable.

- Decreased need for operator skill and experience.

Artificial intelligence (AI) used in laser welding is also good for mass production such as in automotive body shops and electronics manufacturing lines.

Hybrid Laser Welding Techniques

Hybrid welding techniques that mix laser welding with additional techniques like MIG, TIG, or ultrasonic welding are also the way of the future. These systems provide:

- Improved capacity to bridge gaps for imperfect joints.

- Deep laser penetration combined with a variety of filler materials.

- Increased weld strength and reduced distortion.

In the construction, railroad, and shipbuilding sectors, where strong couplings are necessary for large, thick components, hybrid techniques are currently being used.

Ultra-Precision and Microwelding Technologies

Femtosecond and picosecond ultrafast lasers are making it possible to fuse medical implants, delicate electronic parts, and extremely thin metals without causing any harm to the surrounding material. Among the applications are:

- Surgical instruments and microstents.

- Sensors and electronic connectors.

- Microelectronic nanofabrication.

Green and Blue Lasers for Copper and Reflective Metals

Copper, brass, and other highly reflective metals are difficult for conventional infrared fiber lasers to cut through. This problem is being resolved by the most recent green and blue wavelength lasers, which make them perfect for:

- EV battery tab welding

- Connectors for electricity

- Busbars and the connecting of conductive metal

Automation and Smart Factory Integration

There is a growing integration of laser welding devices with:

- Automated arms for intricate 3D welding routes.

- ERP and MES systems for intelligent manufacturing settings.

- Monitoring via the cloud for remote maintenance and diagnostics.

In order to keep up with these developments and assist clients in next-generation industrial settings, machines such as Laser Technologies India's GH Series Laser Welding Machines are built with sophisticated software, AI readiness, and hybrid capabilities.

Conclusion

One of the most sophisticated and adaptable joining techniques in current manufacturing is laser welding. It bridges the gap between automation, strength, speed, and precision in a variety of industries, including electronics, medical, and aerospace. With AI-driven controls, multi-process capabilities, and smarter, greener lasers made to handle even more complex materials and applications, laser welding is expected to develop further as technology improves.

Laser Technologies India provides cutting-edge fiber laser welding systems made to meet the production demands of both the present and the future for manufacturers searching for next-generation solutions.

Are you prepared to begin? For machine demonstrations and professional guidance, get in touch with Laser Technologies India.

"How Does a Laser Welding Machine Work?" is the next topic covered in Laser Welding University.