0.4 Fiber vs CO₂ vs Plasma Cutting: Which One is Right for You?

Businesses frequently have to make the crucial choice of whether to use a fibre laser, CO₂ laser, or plasma cutting machine when cutting sheet metal and other industrial materials. Choosing the best cutting-edge technology can have a big impact on your output, quality, and profitability because each one has its own advantages, drawbacks, and uses.

We explain the distinctions between fibre laser cutting, CO₂ laser cutting, and plasma cutting in this article so you can choose the best option for your company's requirements.

- Technology Basics

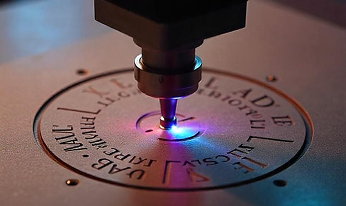

- Fiber Laser Cutting

- Uses a solid-state laser generated through fiber optic cables.

- Emits a beam at 1.06 µm, ideal for metals.

- Beam is focused to a tiny spot, enabling high energy density.

- CO₂ Laser Cutting

- Utilizes a gas laser (carbon dioxide) with mirrors and lenses.

- Operates at 10.6 µm wavelength.

- Well-suited for non-metallic materials.

- Plasma Cutting

- Uses an electrically conductive gas (plasma) to transfer energy to the workpiece.

- Typically used for conductive metals.

- Must have compressed air or gases and a plasma torch.

- Fiber Laser Cutting

- Material Compatibility

- Cutting Speed & Thickness

- Fiber Laser:Fastest cutting speed for thin to medium-thick metals. Great for high-precision sheet metal cutting.

- CO₂ Laser:: Slightly slower, especially on metals. Performs well on thicker non-metals.

- Plasma: Excellent for thick steel cutting (up to 50 mm), but slower on thin sheets with lower accuracy.

- Cut Quality & Precision

- Fiber Laser:Delivers the highest edge quality and detail. Minimal kerf, low HAZ (Heat-Affected Zone). high-precision sheet metal cutting.

- CO₂ Laser:: Smooth finishes on non-metals, good on metals but not as precise as fiber.

- Plasma: Rougher edges, more dross, larger kerf. Best for applications where precision is not critical.

- Operating Cost & Maintenance

- Automation & Smart Integration

- Fiber lasers integrate easily with CNC systems, MES software, robotic arms, and IoT dashboards.

- CO₂ Lasers can be automated but are less common in modern smart factories.

- Plasma cutters offer CNC control but lack finer automation and monitoring tools.

- Investment & ROI

| Material | Fiber Laser | CO₂ Laser | Plasma Cutting |

|---|---|---|---|

| Mild Steel | Excellent | Good | Excellent |

| Stainless Steel | Excellent | Good | Good |

| Aluminum | Excellent | Fair | Good |

| Copper/Brass | Reflective Risk | Not Recommended | Reflective Risk |

| Acrylic, Wood, Plastics | Not Ideal | Excellent | Not Suitable |

Verdict: Choose Fiber for metals, CO₂ for non-metals, and Plasma for thick metal sheets at lower cost.

Laser Technologies’ GH Series Fiber Laser delivers up to 200 m/min movement speed with clean cuts and minimal dross.

| Factor | Fiber Laser | CO₂ Laser | Plasma Cutting |

|---|---|---|---|

| Energy Efficiency | Very High | Low | Moderate |

| Maintenance | Low (No mirrors) | High (Mirrors, Tubes) | Moderate |

| Consumables | Nozzle, Lens | Mirrors, Gas Tubes | Electrodes, Tips |

| Lifespan | 100,000 hrs+ | 10,000–20,000 hrs | 5,000–10,000 hrs |

The GH Series supports Industry 4.0 readiness, making it ideal for smart laser workshops.

| Machine Type | Initial Cost | Long-Term ROI | Ideal For |

|---|---|---|---|

| Fiber Laser | 💰💰💰 | ✅ Highest | Precision fabrication, mass production |

| CO₂ Laser | 💰💰 | ⚠️ Medium | Signage, acrylic, mixed materials |

| Plasma Cutter | 💰 | ✅ Quick Payback | Heavy-duty cutting, job shops |

What Should You Choose?

- Go for Fiber Laser if you want high-precision, energy-efficient metal cutting with automation options.>

- Choose CO₂ Laser if your focus is engraving or cutting non-metals like wood, acrylic, or textiles.

- Opt for Plasma if you need a budget-friendly solution for cutting thick steel and accuracy is less critical.