0.3 Latest Trends & Future of Laser Cutting Technology

Laser cutting technology has evolved over the past ten years from a specialised precision procedure to a major industrial force. Smart, AI-driven fiber laser cutting machines with high-speed automation and Industry 4.0 integration have replaced the initial CO₂ laser cutters used for basic material processing. These days, laser cutting is used in a variety of industries, including metal manufacturing, aerospace, automotive, and prototype, not just for speed but also for accuracy, sustainability, and digital compatibility.

Let’s understand the latest innovations shaping the laser cutting industry and what the next 5–10 years may hold..

1. The Rise of Fiber Laser Cutting Machines

Fiber laser technology has overtaken CO₂ in most industrial applications due to its:

- Higher cutting speed

- Lower operating cost

- Superior energy efficiency

- Ability to cut reflective materials like aluminum, brass, and copper

For example, Laser Technologies' GH Series Fiber Laser Cutting Machines offer up to 30kW laser power, delivering clean, high-speed cuts with minimal downtime. These machines are ideal for sheet metal fabrication, and increasingly, for thicker metals previously reserved for plasma or waterjet cutting.

Trend Insight: Expect to see compact fiber laser solutions tailored for SMEs and multi-head fiber systems that allow parallel cutting in high-volume environments.

2. Smarter Machines with AI & Predictive Maintenance

These days, intelligent cutting assistants are being created by CNC laser systems. These days, AI and machine learning algorithms are:

- Real-time cutting route optimisation

- Forecasting lens and nozzle wear and damage

- automatically modifying power and focus according to material thickness

- Cutting down on training time and human intervention

Laser Technologies India is aligning with this trend through automated systems that allow users to monitor and control cutting performance, gas usage, and system health remotely.

Prediction: AI-powered dashboards and voice-assisted troubleshooting will become standard in high-end machines.

3. Automation & Industry 4.0 Integration

The future of laser cutting is smart, connected, and autonomous. From robotic loading/unloading systems to MES (Manufacturing Execution Systems) and ERP integrations, laser cutting machines are becoming central to digital factories

Key automation innovations include:

- Unmanned operations with smart safety sensor

- Real-time IoT monitoring of laser usage, temperature, gas consumption

- Automated job switching using barcodes and preloaded G-code

Machines like the GH Series support CNC automation and remote production control, making them Industry 4.0-ready.

Trend Insight:Expect cloud-based interfaces to manage multiple laser machines across different plants or geographies.

4. Sustainability: Green Laser Cutting

Eco-conscious manufacturing is driving laser technology to become more efficient and cleaner:

- Fiber lasers consume significantly less energy than CO₂ lasers

- Assist gas optimization is reducing nitrogen and oxygen usage

- Closed-loop cooling systems are minimizing water waste

- Non-contact processing results in lower scrap rates

As global regulations tighten, businesses are choosing eco-efficient machines like Laser Technologies’ GH Series that emphasize energy savings and low emissions.

Future Outlook:Development of direct diode lasers and recyclable laser byproducts for zero-waste manufacturing.

5. Software-Driven Laser Operations

Modern laser cutters are powered as much by software as by hardware:

- CAD/CAM software is now integrated with nesting algorithms, real-time costing, and material tracking

- Operators can simulate cuts before production to minimize material loss

- Augmented Reality (AR) interfaces are emerging for live monitoring

Laser Technologies supports popular laser control software and is working on bringing smart UI and offline simulation tools to Indian workshops.

Prediction: Cloud-based laser design libraries, plug-and-play APIs, and mobile laser operation apps will dominate.

6. Expanding Applications Across Industries

While metal cutting remains core, the range of applications is growing:

- Aerospace: Ultra-high tolerance components

- Medical: Intricate stainless steel implants

- Electric Vehicles (EVs): Copper busbars and lightweight frames

- Prototyping: Rapid iteration on sheet and tube assemblies

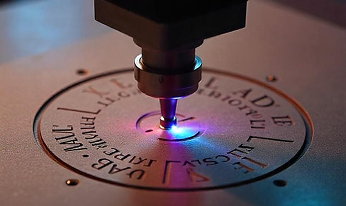

Machines like Laser Technologies' iMark Series demonstrate how CO₂, fiber, and UV lasers can be adapted for marking and engraving in diversified sectors.

Trend Insight: Industry-specific machines with modular heads (cutting, marking, welding) will see rising demand.

7. The Future: Hybrid Lasers, Beam Shaping & Beyond

The following will be part of the next generation of laser cutting technology:

- Beam shaping technology that instantly adjusts the beam width to the material CO2 and fiber are combined in a single chassis in hybrid laser systems.

- Multi-axis 3D and bevel cutting laser heads

- Self-governing laser robots for construction and shipbuilding

- Advanced materials can be micro-cut using femtosecond and nanosecond lasers

These developments could lead to new developments in biology, micromechanics, and electronics by increasing precision, flexibility, and miniaturisation.