0.1 Fundamentals of Laser Cutting

What is Laser Cutting?

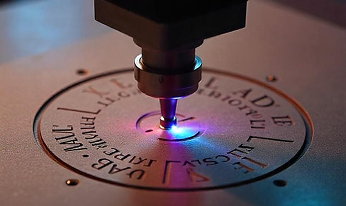

Laser cutting is an advanced manufacturing process that uses a high-powered laser beam to cut, engrave, or etch materials with precision. This method has become widely adopted across multiple industries due to its ability to produce intricate designs with high accuracy and minimal waste. Unlike traditional cutting techniques that rely on mechanical force, laser cutting works by directing a concentrated beam of light onto a material, which melts, burns, or vaporizes the surface, creating precise cuts.

Laser cutting is an advanced manufacturing process that uses a high-powered laser beam to cut, engrave, or etch materials with precision. This method has become widely adopted across multiple industries due to its ability to produce intricate designs with high accuracy and minimal waste. Unlike traditional cutting techniques that rely on mechanical force, laser cutting works by directing a concentrated beam of light onto a material, which melts, burns, or vaporizes the surface, creating precise cuts.

How Does a Laser Cutting Machine Work??

Laser cutting works by directing a high-powered laser beam through a lens system that concentrates the light onto the material. This intense energy causes the material to melt, burn, vaporize, or be blown away by a gas jet, resulting in a clean and precise cut.

Step-by-Step Process:

Generating the Laser Beam – The laser is produced using CO₂, fiber, or crystal-based sources.

Focusing the Beam – Lenses or mirrors focus the beam onto a fine point.

Material Interaction – The focused energy heats and melts the material.

Gas Assistance – Oxygen, nitrogen, or compressed air blows away molten debris.

Controlled Movement – CNC (Computer Numerical Control) guides the laser head to cut as per the programmed design.

What Materials Can Be Cut Using Laser Cutting?

Laser cutting can process metals, plastics, wood, textiles, paper, glass, and composites. The type of laser used determines the range of materials that can be cut effectively.

CO₂ vs. Fiber vs. CNC Laser Cutting: Differences Explained

What is the Maximum Thickness a CO₂/Fiber Laser Can Cut?

CO₂ Lasers: Cut up to 25mm in acrylic and 12mm in mild steel.

Fiber Lasers: Can cut up to 50mm in metals like stainless steel and aluminum.

Fiber Lasers

CO₂ Lasers

CNC Laser Cutting

CO₂ Lasers: Ideal for cutting non-metal materials like wood, acrylic, and glass.

Fiber Lasers: More efficient for cutting metals like stainless steel and aluminum.

CNC Laser Cutting: Uses pre-programmed computer control to ensure high precision in industrial.