0.7 How to Maintain & Troubleshoot a Laser Cutting Machine

A laser cutting machine is a precision tool — and like any high-performance equipment, regular maintenance is essential to ensure longevity, consistent quality, and minimal downtime. Whether you own a fiber laser cutting machine, CO₂ system, or CNC-integrated model, knowing how to maintain and troubleshoot your machine can save time, money, and frustration.

In this Laser Cutting University guide, we’ll walk you through:

- Daily, weekly, and monthly maintenance tasks

- Common laser machine issues and how to solve them

- Tips for maximizing performance

- Internal references to machines like GH Series & iMark from Laser Technologies India

Daily Maintenance Checklist

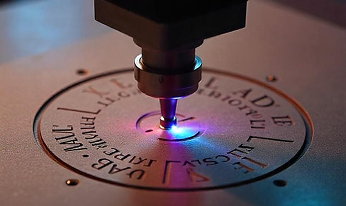

Clean Optics (Lens & Protective Glass)

- Use approved lens wipes or optical cloth

- Avoid touching optics with bare hands

- Look for burn marks, debris, or discoloration

Inspect Nozzles

- Ensure no clogging or buildup

- Misaligned or worn nozzles can cause uneven cuts

Check Assist Gas Lines

- Ensure oxygen/nitrogen/air lines are connected securely

- Listen for leaks or abnormal hissing

Clear Work Area

- Remove metal dust, scrap, and residue from the cutting bed

- Use an industrial vacuum or brush

Weekly Maintenance Tasks

Clean Machine Rails & Linear Guides

- Wipe down with lint-free cloth

- Apply lubrication if required (check manufacturer recommendation)

Drain & Check Chiller/Cooling System

- Make sure the water is clean and topped up

- Look for signs of algae or sediment buildup

Test Focus System

- Verify that the auto-focus sensor (if equipped) works accurately

- Manually calibrate if cuts are shallow or inconsistent

Laser Technologies’ GH Series fiber machines feature an intelligent autofocus head that simplifies focus maintenance.

Monthly Preventive Checks

Software & Firmware Updates

- Check with manufacturer for the latest updates

- Updates may include bug fixes, new features, or improved cutting parameters

Beam Alignment (CO₂ Machines)

- CO₂ systems rely on mirrors; realign using test pulses

- Skewed beam paths can affect power delivery

Filter & Ventilation Inspection

- Clean or replace air filters

- Make sure fume extraction is working properly

For iMark CO₂ systems, consistent beam alignment and air filter cleaning is critical for marking clarity and tube life

Common Issues & Troubleshooting

Problem: Poor Cut Quality

Cause: Dirty lens, misfocus, worn nozzle, low gas pressure

Fix:

- Clean lens and mirrors

- Recalibrate focus

- Check nozzle size and alignment

- Verify gas flow and pressure

Problem: Inconsistent Power or Burn Marks

Cause: Beam misalignment (CO₂), unstable chiller, or power fluctuations

Fix:

- Realign optics

- Inspect cooling water

- Use a voltage stabilizer

Problem: No Laser Output

Cause: Interlocks open, emergency stop engaged, or software crash

Fix:

- Check door and lid interlocks

- Reset emergency stop

- Restart software and machine

Tips to Extend Your Laser Machine's Life

- Use high-quality assist gas to reduce contamination

- Train your team in proper handling and safety

- Log all maintenance activities to track wear trends

- Avoid overworking the machine; use duty cycles appropriately

- Partner with trusted manufacturers likeLaser Technologies India,who offer support, training, and preventive maintenance services

Just like you wouldn’t skip oil changes on a car, your laser cutting machine needs regular attention. A well-maintained machine delivers precise cuts, fewer errors, and longer lifespan — all critical for business success.

Explore Laser Technologies’ GH Series Fiber Laser Machines or iMark CO₂ Marking Systems both built for durability and serviceability, and backed by training and after-sales support.

Up next in Laser Cutting University: "Best Software for Laser Cutting Machine Operation"