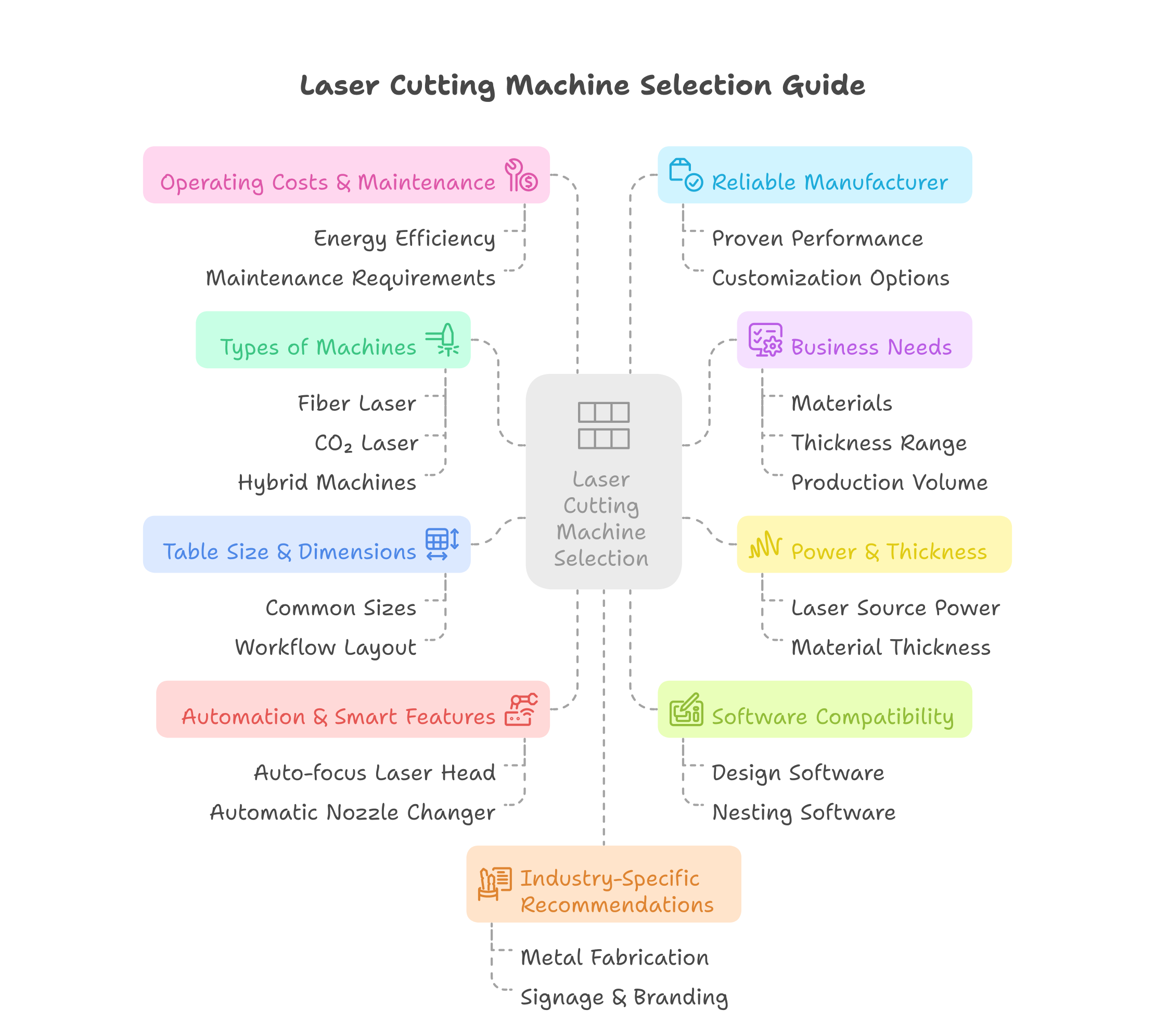

0.5 How to Choose the Right Laser Cutting Machine for Your Business

Investing in a laser cutting machine is a big decision — and choosing the right one can define your business’s success, efficiency, and scalability. Whether you're starting a new venture or upgrading your current setup, this guide will help you make an informed decision.

This Laser Cutting University article covers:

- Types of laser cutting machines

- Key selection criteria

- Industry-specific recommendations

- Internal references to Laser Technologies India’s GH Series, iMark Series, and more

- Bonus: Buying checklist

Understand the Types of Laser Cutting Machines

Fiber Laser Cutting Machine

- Uses fiber optic cable to deliver laser energy

- Ideal for cutting metals — stainless steel, mild steel, aluminum, copper, brass

- Offers high speed, high precision, and low maintenance

Best For: Sheet metal fabrication, industrial manufacturing, electrical panels, auto parts

CO₂ Laser Cutting Machine

- Uses a gas mixture (CO₂, nitrogen, helium) as the laser medium

- Ideal for non-metallic materials — acrylic, wood, leather, textiles, glass, rubber

- Smooth cutting edges, suitable for creative and signage applications

Best For: Acrylic signage, interior décor, gift items, packaging, fashion accessories

Hybrid or Combined Machines

- Combine fiber and CO₂ or integrate cutting & engraving

- Suitable for multi-material, versatile operations

Best For: Businesses offering mixed material cutting and engraving services

Define Your Business Needs

Start by asking:

- What materials will I cut most often?

- What thickness range do I need to handle?

- What’s the expected production volume?

- Do I need automation, or will I start with a manual workflow?

- What’s my budget and ROI timeline?

Scenario Examples:

- If you mostly cut stainless steel sheets up to 12mm for industrial clients → Choose a high-wattage fiber laser.

- If you plan to make custom wood and acrylic designs → Go for a CO₂ laser with creative software support.

Consider Laser Power & Thickness Capability

The laser source power (in watts) directly impacts:

- Speed of cutting

- Thickness of material it can handle

- Cut quality on edges and corners

General Power Guidelines:

| Material Thickness | Recommended Power |

|---|---|

| Up to 3 mm | 1–2 kW Fiber |

| 3–6 mm | 2–3 kW Fiber |

| 6–12 mm | 3–6 kW Fiber |

| 12 mm+ | 6–15 kW Fiber |

| Non-metals (Acrylic/Wood) | 80–150W CO₂ |

GH Series offers power options up to 30kW, enabling fast and clean cuts on thick metals.

Evaluate Table Size and Bed Dimensions

Larger sheets = fewer cuts = higher efficiency.

Common Sizes:

- 1300 x 900 mm – Entry-level workshops

- 1500 x 3000 mm – Mid-level industrial use

- 2000 x 4000 mm – Heavy-duty fabrication

Choose a machine size that matches your material sheet size, storage space, and workflow layout.

Pro Tip: GH Series machines from Laser Technologies are available in customizable table sizes.

Look for Automation & Smart Features

Modern businesses need speed + efficiency. Automation features reduce human error and increase ROI

Look for:

- Auto-focus laser head

- Automatic nozzle changer

- Auto-loading & unloading systems

- Live diagnostics & remote monitoring

- Intelligent nesting software integration

GH Series machines support Industry 4.0 features and IoT dashboards for real-time production insights.

Software Compatibility

Your machine must work seamlessly with:

- Design software: AutoCAD, CorelDRAW, Illustrator

- Nesting software: SigmaNEST, Lantek, CypCut

- CNC control software: Ruida, Beckhoff, FSCUT

The iMark CO₂ series supports CorelDRAW and Adobe Illustrator for seamless engraving workflows.

Operating Costs & Maintenance

Fiber Laser:

- High energy efficiency

- Low maintenance (no mirrors, gas tubes)

- Long lifespan (up to 100,000 hrs)

CO₂ Laser:

- Higher energy consumption

- Requires periodic mirror alignment and gas tube replacement

Choose a vendor that offers:

- Easy availability of spares

- Prompt technical support

- Preventive maintenance contracts

Choose a Reliable Manufacturer

Buy from a trusted brand with proven industrial performance, like:

Laser Technologies India

- Offers a wide range of fiber, CO₂, tube, and hybrid laser cutting machines

- Known for GH Series (fiber) and iMark Series (CO₂ & marking)

- Provides customization, training, warranty, and AMC support

Industry-Specific Recommendations

Metal Fabrication Units

- Use: Mild steel, stainless steel, aluminum

- Go For: GH Series Fiber Laser (3kW–15kW)

Signage & Branding

- Use: Acrylic, MDF, foam boards

- Go For: iMark CO₂ Laser (100W–150W)

Electrical Cabinet & EV Part Manufacturing

- Use: Copper, aluminum, stainless steel

- Go For: High-wattage Fiber Laser (6kW+) with precision control

Small-Scale Design Studios

- Use: Paper, leather, plywood, soft materials

- Go For: Entry-level CO₂ laser machine with a compact footprint

Tube and Pipe Cutting

- Use: Hollow sections, pipes

- Go For: Fiber Tube Laser Cutter with rotary attachmen

Bonus: Laser Machine Buying Checklist

✅ Do I know my primary materials and thickness range?

✅ Have I selected between fiber, CO₂, or hybrid?

✅ Have I accounted for space, ventilation, and power supply?

✅ Does the machine support automation & smart control?

✅ Is software compatibility with my team’s tools confirmed?

✅ Am I purchasing from a reliable vendor with AMC?

✅ Have I budgeted for operating and maintenance costs?

✅ Will the machine scale with my business in 3–5 years?

Choosing the right laser cutting machine is about more than price — it’s about matching your business vision with the right technology. The machine you choose should help you reduce costs, improve precision, and handle increasing demand as you scale.

With reliable models like the GH Series Fiber Lasers and iMark CO₂ Systems, Laser Technologies India helps businesses like yours grow with speed, service, and scalability.