0.9 How to Start a Laser Cutting Business: Step-by-Step Guide

Establishing a laser cutting company can be a very lucrative and expandable endeavour. There are many uses for laser cutting, regardless of whether you intend to cater to the metal manufacturing, signage, automotive, interior design, fashion, or jewellery industries. You may create a profitable company that serves both B2B and B2C sectors with the correct strategy, tools, and location.

We walk you through every important step to launch your laser cutting business in this Laser Cutting University handbook.

Identify Your Business Niche

Laser cutting is a versatile service, so identifying your target market early helps streamline decisions.

Common niches include:

- Metal fabrication (B2B)

- Acrylic & signage (retail & business branding)

- Custom gifting & décor (weddings, corporate gifts)

- Jewellery & fashion accessories (precision CO₂ & fiber work)

- Industrial prototyping(automotive, aerospace, electronics)

Tip: Research local demand and competitor offerings before selecting your niche.

Create a Business Plan

A clear business plan helps you stay focused and attract investment

Include:

- Mission & vision

- Market research & competitor analysis

- Services & pricing

- Initial investment & running costs

- Marketing & sales strategy

- Growth roadmap

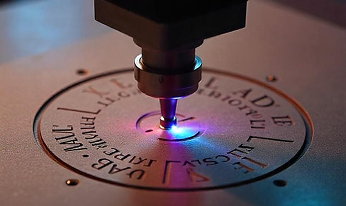

Choose the Right Laser Cutting Machine

Your business depends on the quality and capabilities of your laser cutting machine. Consider factors such as cutting speed, precision, and material compatibility when selecting the right machine for your specific niche

Machine Types:

- Fiber Laser – Best for cutting metals (steel, aluminum, brass)

- CO₂ Laser – Ideal for wood, acrylic, leather, plastics

- Hybrid Machines – Offer cutting and engraving across materials

Recommended:

- GH Series Fiber Laser Cutting Machines – For industrial metal cutting

- GH iMark CO₂ Series – For non-metallic cutting & engraving

Set Up Your Workspace

Depending on your business scale, your workspace could be a:

- Small workshop (for custom jobs and retail orders)

- Industrial unit (for bulk B2B production)

Considerations:

- Proper ventilation & dust extraction

- Chiller unit space (for cooling the laser)

- Power supply (especially for high-wattage fiber lasers)

- Secure storage for raw materials and finished parts

Legal Setup & Certifications

Ensure your business is legally compliant:

- Register your company (proprietorship, LLP, Pvt Ltd.)

- Obtain GST number and necessary local licenses

- Set up business banking & invoicing tools

- Check for safety and environmental compliance (especially for fumes/gases)

Tip: Maintain an MSDS (Material Safety Data Sheet) library for the materials you cut.

Choose the Right Software

Laser cutting success isn’t just about the machine — software plays a huge role.

Essential Tools:

- Design Software: AutoCAD, CorelDRAW, Adobe Illustrator

- Nesting/CAM Software: SigmaNEST, Lantek, CypCut

- CNC Operation & Simulation: Ruida, Beckhoff, or proprietary controllers

See our guide: Best Software for Laser Cutting Machine Operation

Build Your Team (Optional for Scaling)

In the beginning, you can start solo or with a small team.

As you grow, you’ll need:

- Machine operators

- CAD/CAM designers

- Sales & customer service reps

- Value-added services (design, packaging, shippining)

Pricing Your Services

Factor in:

- Machine depreciation

- Electricity, gas, and material costs

- Labor time (per piece or hour)

- Value-added services (design, packaging, shipping)

Use a costing template and revise prices based on market demand.

Marketing & Customer Acquisition

Start building your brand and digital presence:

- Create a professional website with service listing and quote form

- Use Instagram, LinkedIn, and Facebook for portfolio marketing

- List on Google Business, JustDial, IndiaMart, and local directories

- Run ads for B2B leads or local artisan communities

Offer free samples or discounted trials for your first 10 clients

After-Sales, Support & Growth Strategy

- Implement CRM tools to track clients and orders

- Offer maintenance services, repeat orders, or design upgrades

- Collect testimonials & Google reviews to build credibility

- Attend expos like IndiaCorr Expo, IMTEX, or ACETECH to network and scale

Explore scaling into allied services like laser welding, marking, or fabrication consulting as you grow.

Starting a laser cutting business is a blend of technology, creativity, and strategy. With the right foundation — a niche, reliable equipment like GH Series Fiber Lasers or iMark CO₂ Machines, proper planning, and strong customer service — you can build a business that cuts through the competition.

Up next in Laser Cutting University: “10 Profitable Business Ideas with a Laser Cutting Machine”