0.2 Types of Lasers Used in Cutting Machines (Fiber vs CO₂)

Laser cutting machines are typically defined by the type of laser they use as their energy source. The two most common laser types in modern cutting are CO₂ lasers and fiber lasers, each with unique characteristics. Regardless of the type, virtually all modern laser cutters are integrated with CNC systems for automated control. Let’s look at these laser types:

- CO₂ Laser Cutting Machines: CO₂ lasers are gas lasers that generate a laser beam using a mixture of gases (primarily carbon dioxide, plus others like nitrogen and helium) excited by electricity. These lasers emit infrared light at about 10.6 µm wavelength. CO₂ laser cutting was the industry standard for many years and is still widely used. They are especially effective for cutting non-metal materials (wood, acrylic, plastics, fabrics) because materials that are transparent to visible light often absorb CO₂ laser light well. CO₂ lasers can also cut metals – in fact, high-powered CO₂ lasers have been used to cut steel, stainless steel, and aluminum for decades. Historically, CO₂ systems were preferred for cutting thicker mild steel and stainless steel, partly because the 10.6 µm beam produces a very smooth cut edge on certain metals. CO₂ laser cutters usually have a large resonator tube and use mirrors to deliver the beam to the cutting head. They require alignment and maintenance of optical components, and the gas tubes need replacement or recharging over time. Many CNC laser cutting machines in job shops up through the 2000s were CO₂-based. Even today, CO₂ lasers remain popular for applications like laser cutting of organic materials (e.g. leather, wood) and in lower-cost hobby or sign-making laser cutters. (Fun fact: the common laser engravers that cut wood or acrylic artwork are often CO₂ laser machines in the 30–150 W range, much lower power than industrial cutters.) In an industrial context, CO₂ lasers can be very powerful (e.g. 6 kW or more) and handle large format cutting. Laser Technologies India also offers CO₂ laser systems – for example, their iMark CO₂ series is used for high-precision laser marking, demonstrating the versatility of CO₂ lasers across cutting and marking applications.

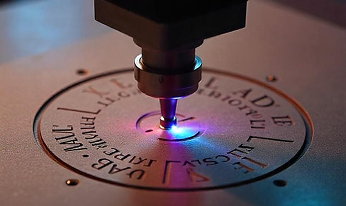

- Fiber Laser Cutting Machines: Fiber lasers are a type of solid-state laser that generate the beam using a special fiber optic cable doped with rare-earth elements (such as ytterbium). They emit laser light in the near infrared spectrum (~1.06 µm wavelength). The laser light is amplified within flexible fiber optics, so the beam can be delivered to the cutting head via a fiber cable rather than open free-space optics. Fiber laser cutters have surged in popularity in the last 10–15 years because they offer several key advantages for metal cutting. First, the shorter wavelength (around one-tenth of a CO₂ laser’s wavelength) is absorbed more efficiently by metals, which means fiber lasers can cut metal faster and with less energy. Fiber lasers also produce a very small focused spot size, yielding high power density for rapid cutting. Second, fiber laser machines are generally more energy-efficient – often converting 30-50% of electrical power into laser light, whereas CO₂ lasers might achieve 10-15%. This makes fiber systems more economical to operate. Third, they are lower-maintenance: there are no mirrors that need regular cleaning or alignment in the beam delivery, and the solid-state fiber laser source can last tens of thousands of hours. For these reasons, fiber lasers have become the go-to solution for industrial laser cutting of metals (steel, stainless, aluminum, copper, brass, etc.). For example, the earlier-mentioned GH Series is a fiber laser cutting machine capable of cutting thick sheet metal at high speed, something that would be challenging for older technologies. Fiber laser cutters excel at sheet metal laser cutting with high precision and can even handle reflective metals (like copper or brass) better than CO₂ lasers, which sometimes struggle with back-reflections. It’s worth noting that fiber lasers are part of a broader category of solid-state lasers (which also includes older Nd:YAG crystal lasers), but fiber designs have largely overtaken others in cutting applications due to their efficiency and beam quality. Today, if you hear about a new laser cutting machine being installed in a factory, odds are it’s a fiber laser model.

Other laser types: Besides CO₂ and fiber, there are also Nd:YAG and disk lasers (solid-state lasers used in some cutting systems), and newer ultrafast lasers for specialized precision cutting, but these are less common for general cutting of sheet and plate.Laser Technologies India’s iMark series actually spans multiple laser types (offering fiber, CO₂, and even UV lasers for marking), which showcases how different laser sources are chosen for different tasks – fiber for fast metal processing, CO₂ for versatile material use, and UV (355 nm) for extremely fine marking on sensitive materials. Understanding the differences between these laser types helps in selecting the right laser cutting machine for a given application.

Advantages of Laser Cutting in Modern Industry

Laser cutting offers many advantages over traditional cutting methods (such as sawing, punching, or plasma cutting). Here are a few advantages of laser cutting in industry:

Accuracy: Laser cutters can achieve extremely tight tolerances and fine detail. The laser beam can be less than 0.1 mm in width, allowing for high-precision cuts and the ability to cut intricate shapes or patterns that would be impossible with a mechanical tool. This precision is ideal for industries like aerospace, automotive, and electronics where accuracy is critical.

High Cutting Speed: Laser cutting is very fast, especially for thin and medium-thickness materials. A high-power fiber laser cutter, for instance, can slice through sheet metal at a much faster rate than a bandsaw or waterjet for the same job. Moreover, since it’s CNC-automated, the laser can run continuously with minimal downtime between different cuts. This production efficiency means higher throughput on the shop floor.

Versatility in Materials and Thickness: A single laser cutting machine can cut a wide variety of materials – from metals (steel, stainless, aluminum, titanium) to plastics, wood, fabric, and more (with the appropriate laser type and settings). It can also handle a range of thicknesses by adjusting power and focus. For example, industrial lasers can cut thin foils just as precisely as heavy plate steel (though very thick metal may require higher power or multiple passes). This versatility makes lasers useful in many industries, from sheet metal fabrication to signage, medical device manufacturing, and beyond.

Complex Cuts with No Tool Change: Because the cutting path is just programmed in software, lasers can cut complex contours, sharp corners, and delicate interior cut-outs all in one operation. There’s no need to switch tools for different shapes – the same laser “tool” does everything. This ability to create unlimited 2D geometry in a single step is a huge advantage over mechanical processes. It reduces setup time and simplifies the fabrication of complicated designs.

Clean Cuts: BLaser cutting often produces a very clean edge finish. The heat-affected zone is relatively small and with proper settings, there is little to no burr on metal parts. Also, since there’s no physical blade dragging on the material, there’s no distortion on thin pieces. The result is that parts come off the laser machine nearly ready to use, usually without the need for extensive deburring or finishing.

Reduced Waste and Contact-Free Cutting: The laser’s narrow kerf means it wastes very little material – parts can be nested closely on a sheet to maximize material usage. Additionally, laser cutting is a non-contact process, which not only means no tool wear (the laser doesn’t dull like a saw blade would) but also no mechanical force on the workpiece.

Easy Automation and Integration: Laser cutters are highly compatible with automation. They can be equipped with CNC controls (as they typically are), robotic loading/unloading systems, vision systems for alignment, etc. This makes them a central component in modern smart manufacturing and Industry 4.0 factories. Once programmed, a laser cutter can run unattended, improving productivity. The flexibility of laser cutting also means you can go from design to part very quickly – ideal for custom jobs or rapid prototyping and mass production.