If you are someone who is new to the world of laser marking, then it is a very propitious time for you. This is so because this particular industry possesses old and new technologies that come together to make "marking" an extremely interesting, genuine, and profitable operation.

You must know one thing, today, none of the technologies are as intriguing and flexible as fiber laser marking technology. In this blog post, we are going to introduce you to the technology of fiber laser marking, its industrial applications, materials used, and many other things. After you finish reading this article, you will be able to specify how this is the best for your utilization.

Let's get started!

What Is Fiber Laser Marking?

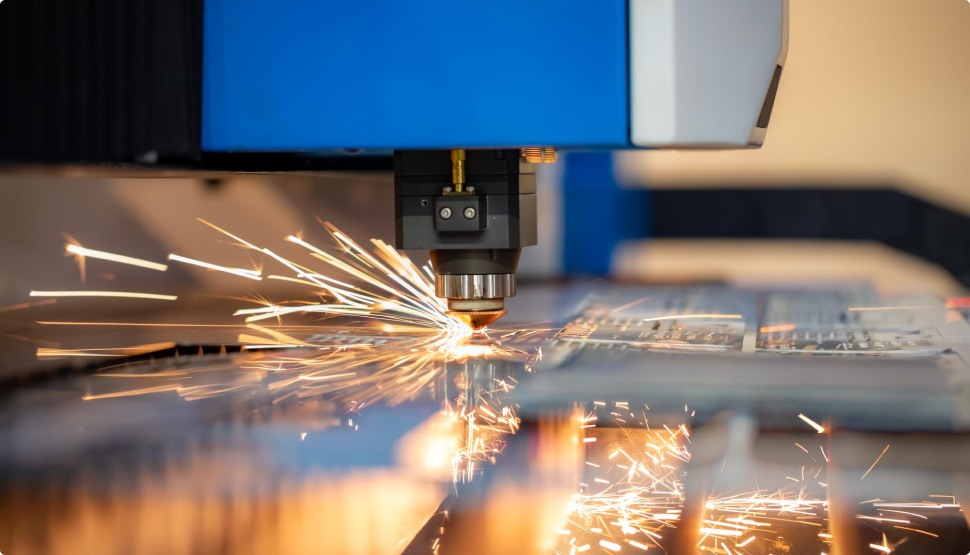

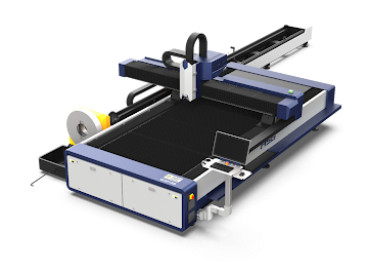

A fiber laser machine significantly has three prominent parts, which include — the resonator, the pump, and the beam delivery system. So, the pump consists of laser diodes, and from this, a light beam is emitted and then transmitted through fiber optics to a resonator which actually holds the gain medium. Now, the resonator truthfully hosts the gain medium, which in simple words, is none other than a fiber optics medium loaded with unique earth substances.

Here, the major differences between distinct fiber laser applications are completely based on the generated wavelengths, which on the other hand helps in determining the surfaces that can have a mark on them. When it comes to metal markers, they are mainly doped with Ytterbium, providing them with the wavelength that is required for maximum absorptivity for substance marking on several plastics and metals. Then the resonator mixes the gain medium with a group of semi and full-reflecting Bragg grating elements that enable for application, refraction, and filtering of light waves to get the perfect wavelength needed for marking.

Next, the filtered beam is transmitted into the beam delivery system, which is also known as the beam expander and has a lens fitted in a beam head. And this is the "laser pen," which is responsible for making the markings on the materials. The main advantage of fiber laser marking is its flexibility and versatility in marking diverse substances, hence making it the most selected marking and engraving method in so many industries.

The data marked on the substances can also be selected without hassle, which ranges from numbers, texts, logos, images, codes, etc. Moreover, in laser marking, color change is a common procedure that is utilized. This process delivers high-contrast labeling on the materials without causing any harm or damage to the surface. Also, in this whole procedure, the laser ends up heating the substance at the intended regions precisely, thus delivering a high-quality contrast color change on the substance.

Fiber Laser Marking Machine — "Industrial Applications"

By now, you must know that a lot of industries involve fiber laser marking machines in their day-to-day operations. So, here are some of the industrial applications of this specific machine explained below:

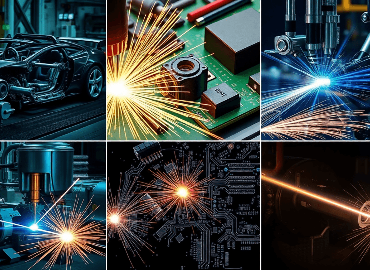

➤ Electronics Industry

In a fast-developing industry like this, it becomes extremely important that efficiency & integrity are kept first on the priority list. It needs to match the increasing demands of the industry. This ever-increasing demand also expects safety and quality as well. Electronic devices such as smartphones, TVs, and laptops are all made up of tiny elements. Fiber laser marking is one of the most efficient techniques utilized for marking in this industry because it can work with tiny elements without causing any harm to them.

➤ Automotive industry

When it comes to the automotive industry, it has come to be the largest user of laser technology. It is assumed that a single car is created out of roughly thirty thousand parts or elements, which are made up of copper, steel, aluminum, plastic, special fiber, etc., all of them having varied shapes & sizes.

Here are a few applications in which part-making is accomplished by utilizing a fiber laser marking machine in the automotive industry:

(a) Marking several elements and buttons on the present dashboard. They must be visible very well during the day and must be illuminated at night. Hence, day and night markings are utilized.

(b) Marking the components of seat belts with vital information such as serial numbers, barcodes, or country of origin.

(c) You might also be able to discover fiber laser markings on automotive sensors, engine locks, motorcycle parts, etc

(d) Many other substances, such as ceramics, utilized to develop spark plugs can also be marked by utilizing this technique as well.

➤ Medical Industry

Health manufacturers and institutions of medical tools & equipment have extremely strict standards when it comes to the size, content, and position of the marking, thus leaving zero chances of any mistakes. The markings should be resistant to being cleaned with acids, sterilization & corrosion, and high temperatures. The tools might become small & tiny, and the procedure becomes more efficient. But, safety and quality must remain prioritized in this industry. Therefore, fiber lasers have become so popular when it comes to markings in this industry by taking into account their accuracy, adaptability, quality, cost-effectiveness, and reliability.

Below mentioned points are some of the general reasons why fiber laser markings are utilized in the healthcare sector:

(a) Enhanced traceability of individual biofluid storage containers.

(b) Quick traceability of tools & equipment because the medical personnel in health institutions must be able to track and locate the medical devices rapidly in hospitals.

(c) Better identification of prostheses, i.e., medical prostheses require a medical number or code that is based on alphanumeric series collected from a database.

What Type Of Substances Can Be Marked Using A Fiber Laser Marking Machine?

Fiber laser marking machines have worked competently on a wide spectrum of substances, given they are brittle, tough, hard, or dark. This specifies that most metals and non-metals, such as plastics, can function well when hit by fiber laser in order to generate high-contrast markings. For some of the substances, such as plastics, CO2 laser marking machines, and fiber laser marking machines, both of them can be utilized efficiently. However, the effect or the result might vary a little, and the cost of different systems can also become a matter of consideration.

The materials that can be marked by using a fiber laser marking machine are — Carbon Fiber, Steel, Aluminium, Plastic, Steel, etc.

Conclusion

Today, we have studied fiber laser marking in-depth, and now we are aware of its uses and shortcomings as well. These types of laser machines help in implementing the utilization of a laser beam in order to engrave solid or permanent markings on the surface of the materials. They are utilized to make a wide variety of content on so many types of substances.

Fiber lasers are utilized in many industries, as you already read above; this is so because they can mark even tiny little substances, and further, it is utilized in jewelry industries to engrave brand identities. They can be used on metals, carbon fiber, plastics, etc. They come with their own advantages as well as challenges, but so far, they have been proven to be the best in the market.

For more updates, visit our website regularly! And in case of any queries, reach out to us anytime.