In the industry of lasers, there's a common debate that goes round and round every single time. Can you guess what it is about? Well, you might have gotten an idea by just reading the title of this article. Yes, it's "Fiber Laser versus CO2 Laser!"

These two laser technologies are widely available in the manufacturing sector. Many people like to believe that fiber lasers are the ones that bring various inventions to the table, which makes them the best, whereas others think that CO2 lasers are much better because of their capabilities.

However, the straightforward explanation of the fiber laser vs CO2 laser debate relies on the application type. Remember that no technology can be compared and be better than the other; it just suits different situations or people. The perfect decision totally relies on your application and many other factors such as material properties, precision, sustainability, quality of work, and much more.

Today, the following text will take you on a ride to look at what fiber and CO2 lasers are here to provide you and learn about their differences!

Get ready to address the cutting debate between fiber laser cutting vs CO2 laser!

CO2 Lasers — Explained

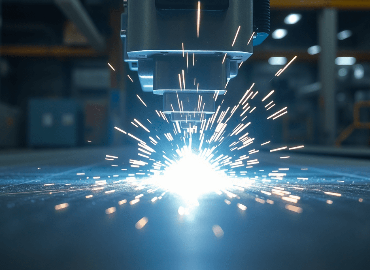

Purging gases, a mixture of a resonator and high-velocity blowers, are utilized by CO2 lasers to develop high-powered light elements. This is done to observe a collision between these so that high-intensity light can be delivered that will be able to cut through thicker substances with proximate comfort.

In contrast to fiber lasers, CO2 lasers possess a beam path delivery system that originally functions differently by utilizing the method of reflection and refocusing instead of focal lenses similar to fiber lasers.

Chiefly, CO2 lasers are much better at being expensive when compared to fiber lasers. Nonetheless, the lower preliminary expense does not imply that it is more reasonable and economical. Plus, CO2 lasers consume a lot of energy, leading to extremely high operating prices.

Advantages Of CO2 Lasers

- Excellent Quality

CO2 lasers are amazing at providing a better finish when it comes to aluminum substances and stainless steel.

- Prevailing For A Really Long Time

CO2 lasers have existed for a long period of time, i.e. more than thirty years; therefore, many experts are there in the market are well aware when it comes to dealing with the wider issues associated with CO2 lasers. This builds a good level of confidence in the user.

- Highly Flexible

These types of lasers are known to be versatile in nature. They offer flexibility across many laser applications, be it metal, non-metal, or any other composite elements, without any refinements.

Disadvantages Of CO2 Lasers.

- Difficulty In Maintenance

When it comes to CO2 lasers, they need appropriate conditions to carry on with their operations and demand various requirements that might disrupt the normal procedures of the industry.

- High Expenses

The high demand for maintenance in CO2 lasers, which require a lot of resources and time, incurs high costs. There are a lot of elements in the beam path delivery system that need regular care & maintenance. Thus, consuming a lot of energy. All of this considerably sums up the all-around cost of utilizing the lasers.

- Reduced Speed

When a comparison is drawn between these two lasers, CO2 lasers are proven to take a much longer time to complete their procedures. When the situation is about working on the thinner parts, CO2 lasers are not proficient enough to complete it. For example - a 4KW CO2 laser with mild steel material and N2 purging gas. This laser might possess a cutting speed of 260 IPM, but when it comes to a fiber laser of the same power, it will achieve a cutting speed of approximately 1400 IPM.

Fiber Lasers — Explained

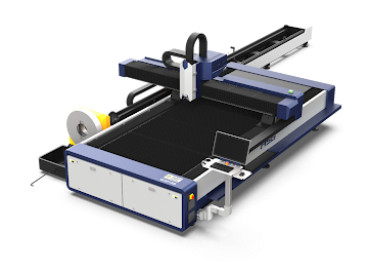

Fiber lasers make use of high-tech fiber optic elements so an intense beam of light can be delivered to cut through various types of materials effortlessly. Fiber lasers are the best for metal processes such as engraving, etching, annealing, etc. The widespread notion and procedure of fiber lasers are exceptionally versatile and easy. The term does not comprise the light source, which is too different from CO2 lasers.

Its sole emphasis is mainly on the release mechanism that utilizes fiber optics to focus all the light on an individual point. Talking about the operating mechanism of fiber lasers, they tend to reflect this kind of clarity. The fiber optic present in the laser cutter attains the light and intensifies it to the laser indicator.

Here, the cutting head utilizes CNC for accuracy and precision. Also, the fiber optic has a procession of following focal lenses that strengthen & improve the prevailing exactness of the entire operation. Eventually, the laser cutter utilizes NO2 or O2, any one of them, as a purging gas to stimulate the cutting process.

Advantages Of Fiber Lasers

- Good Quality

Here, the optical fiber technology tends to contribute additional strength and accuracy that provides you with a smaller cutting line and solid execution for all laser cutting product layouts.

- Reasonable

When fiber lasers are compared with other options, regulating fiber lasers is relatively precise and needs the least training & practice.

- Quicker And Reliable Cutting

Fiber lasers are popular because they have the quality reliability and capability to refine things more shortly because of their high intensity.

- Elevated Efficiency

Fiber lasers amass almost 30% higher electro-conversion efficiency, which says that you can do better & more with less energy.

Disadvantages Of Fiber Lasers

- High Costs While Purchasing

With fiber lasers, the operating costs are definitely low, but the across-the-board investment you require to acquire a fiber laser is relatively huge.

- Consumption Of Gas

Fiber lasers utilize O2 or NO2 gas for elimination and consume a lot of gas. This can prove to be a nuisance for laser operators.

Difficulty In Dealing With Some Substances - Fiber lasers have few difficulties in dealing with reflective materials such as Copper and Aluminum. Further, fiber lasers are likewise unfit to handle some heavier specimens effectively.

Conclusion

If you measure according to the all-around expenses, which include buying, maintaining, or functioning a laser cutting setup, a service like sheet metal fabrication would be the best choice. Laser Technology is the most reputed company in the market because it focuses on providing better quality work and consistency at the most robust price.

When it comes to sheet metal cutting or any other applications, we have our own team of experts who are completely equipped with industry knowledge and are aware of the latest tools in the market.

We can provide you with the best of service with our expertise and experience in this field. Furthermore, we establish ourselves distant with our progressive strategy that is exclusively online. You can easily upload the part dimensions and other classifications to receive a quick quote and begin with the amazing procedure!