With the introduction of the laser cutting machine, everything changed in the manufacturing industry. Now, they can flawlessly reproduce the designs & layouts drawn on the computer in just a few moments or even in a few seconds. In order to cut the materials, lasers are used by laser cutting technologies. This technology is deeply adored & respected by industrial enthusiasts and is extensively utilised in various industrial applications. Let’s have a look at what is meant by an industrial laser cutting machine and what are the different types of lasers that prevail, and what are the results that they can accomplish.

What is an industrial laser cutting machine?

A laser cutting machine can also be referred to as a CNC machine. Here, CNC stands for Computer Numerical Control, and the name originated from the fact that CNC machines take controls from sketches that have been digitised and restored into computer language that describes each and every angle & curve of the designed structure.

After the completion of the drawing on the computer, the designs that are created by the designers need to be sent to the machine. This is very much similar to sending an image to a particular printer.

The most crucial factor is that the laser cutting machine can reproduce all these sketches in a very short span of time and can generate as many pieces as you wish.

How does the industrial laser cutting machine work?

There are various distinct categories of lasers that are utilised in CNC machine tools, but if you observe them closely, all the laser cutting machines function in the same way.

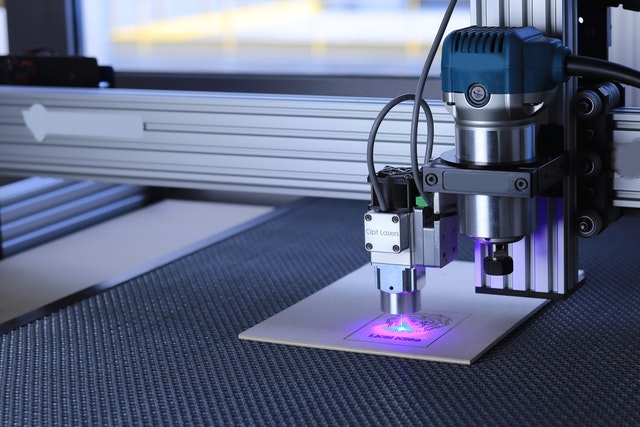

It all begins with a laser source, which generates a powerful, influential and uniform light that can be modified accurately and instantly.

After that, the light is focused and redirected until and unless it touches a decent point. If you have ever utilized a magnifying glass and sunlight together to give rise to a fire, you will be aware of the fact that how it functions. When the light is focused adequately, it becomes extremely hot and can permeate into the substance of your preference.

The laser is generally established on a gantry system, and this enables the laser to move anywhere across the X-Y axis. This suggests that it doesn't matter how many curves and angles are included, the design can be reproduced precisely.

In simple words, not all lasers can generate the exact same level of detail. Some lasers are not powerful enough to cut metal.

"The type of laser specifies what kind and thickness of substance it can cut through because different types of lasers have different power ranges."

Types of laser cutting

There are two major types of laser cutters: CO2 lasers and neodymium lasers. However, these laser cutters are all created in a very similar way, and they are different from each other as each type of laser has a certain power range. Thus each can be utilised to cut through different thicknesses and thicknesses.

CO2 Lasers: The laser is produced from electrically energised gas mixtures which are primarily Carbon Dioxide. CO2 lasers are the most widespread types of laser cutters due to their low power, fairly inexpensive & productive, and can be utilised to cut through numerous kinds of substances.

For example - leather, wood, cardboard, acrylic, glass or some other plastic structures.

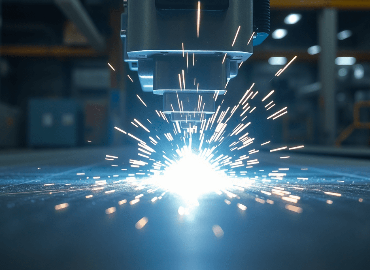

Neodymium Lasers: The laser is constructed from neodymium-doped crystals. This type of laser has a much higher intensity, and hence, it can cut through much thicker substances.

For Example - metal, ceramics and plastics.

Your Next Innovation Starts Here—Explore the Best Laser Cutting Machines for 2025!

How to choose a suitable industrial laser machine?

Always remember, before making a massive investment in a laser machine or any other expensive stuff, try to research it. However, we have come up with a few things that you should consider before purchasing a laser cutting machine:

1)What materials do you want to process?

It depends on the material that you prefer to engrave or cut, which interprets the type of laser you require. If you expect to process organic materials, for example - glass, paper, leather or wood, then you will need a CO 2 laser. Also, you will need a fibre laser to create a mark on the metal or plastic.

Here's a guide to buying a fiber laser cutting machine in 2025.

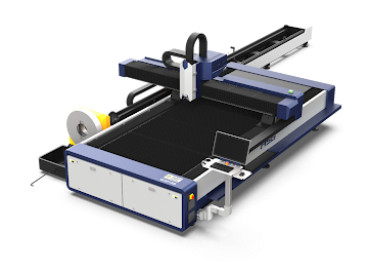

2)Size of the working area: How large are your workpieces?

The size of the workpiece to be engraved or cut specifies the size of the laser machine you would need. Furthermore, the amount of workpieces per order also plays a significant role. If there are multiple items in your order, then you can process them in one strategy. Thus, this will help you in saving a lot of time and also increases the productivity rate.

3)How do you want to utilise your laser, and how much laser power do you require for this?

When selecting the laser power of a laser cutting machine, the essential aspect is the application of the laser that you want to use frequently.

4)Select the right supplier

The most important thing for the prosperity of your business is the reliability factor of the laser cutting machine. This is because only a fully functional device can assure you of the reliability and the integrity of your outcomes. Laser Technology is a highly-skilled and professional manufacturer as well as supplier of industrial laser cutting machines. We possess industrial laser cutting machines with various capacities. If you have any issues or queries related to laser machines, you can contact us anytime, and we will help you decide on the most favourable laser cutting machine, especially for you.

Also Read, A Fiber Laser Machines Price Guide In India: Understanding the Investment

Conclusion

We hope that this article has been successful in solving all your queries related to laser cutting machines and you find this information valuable & helpful and we also hope that by reading this article, you will be able to make an informed decision on whether laser cutting is your best option or not.

If you require any assistance in deciding, please feel free to contact us.