The laser industry is incredibly diverse in itself, providing a number of applications and possibilities for creativity. And, one of the most common questions that is frequently asked by a lot of people is the difference between a laser engraving machine and a laser cutting machine! Both are advanced technologies that have transformed art and industries.

They both utilize lasers with incredible precision but serve different purposes. In this article, learn the difference between these two machines, their uses and how they contribute to manufacturing and design. Whether you are an enthusiast, artist, or professional, this guide will help you apprehend these technologies and their functions in the modern world!

What Is Laser Engraving?

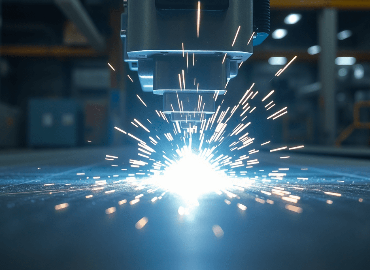

Laser engraving is a complicated method that pertains to utilizing a focused laser beam in order to etch patterns, designs or text on different types of materials. This specific process is considered to be highly precise, enabling intricate detailing as well as customization. The intensity of the laser tends to cause the surface of the material to vaporize or transform its colour, which leaves a permanent mark on the operated substance. The depth of the engraving can be regulated by simply adjusting the power of the laser and the time of exposure.

Laser engraving machines are normally utilized in different industries, including signage, manufacturing, jewellery design, arts and crafts, customization of products, etc. They provide excellent advantages like versatility, precision, speed and the capability to reproduce intricate designs that may be tough or quite impossible to accomplish via traditional engraving techniques.

The laser engraving process is a non-contact method, which helps in minimizing the risk of material damage, and it generates consistent outcomes without the requirement for physical force. Different types of lasers, such as fibre lasers and CO2 lasers, are utilized counting on the substance that has to be engraved and the desired level of detail required.

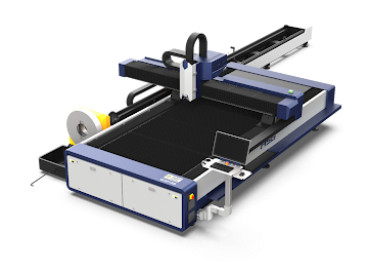

What Is A Laser Cutting Machine?

A laser cutting machine is defined as precise equipment that is utilized for cutting a wide range of substances with high levels of efficiency and accuracy. It makes use of the focused energy of a laser beam to melt, vaporize or burn through the substance, delivering a precise and clean-cut edge. Laser-cutting machines are generally utilized in numerous industries which include aerospace, automotive, manufacturing, medical, electronics and beyond.

Laser-cutting machines are recognised for their proficiency in creating intricate shapes, smooth edges, and less material waste. They are utilized for cutting a wide range of components, enclosing metals (such as steel, aluminium, and titanium), plastics, wood, fabrics, ceramics, and many more. The precision and versatility of laser cutting machines make them a piece of beneficial equipment for both prototyping and large-scale production in assorted industries.

What Are The Differences Between Laser Engraving And Laser Cutting? Explained In Detail

1. Waste and Debris

Laser engraving generates the smallest amount of waste, as it eliminates a thin layer of material from the surface.

Laser cutting tends to produce more waste in the form of vaporized or melted elements, which have to be cleaned or extracted from the work region right after the process is done.

2. Material Thickness

Engraving can be conducted on both thin and thick substances, as long as the laser power and focus are adjusted in an appropriate manner.

Laser cutting is more adequate for materials that are of moderate thickness, as exceptionally thick substances may need multiple passes or some special kind of equipment.

3. Edge Quality

It comes to laser engraving methods, it typically results in smooth and shallow marks on the surface of the material with minimal consequence on the edge quality.

Laser cutting can produce clean and precise edges, but the quality might vary depending on the material type and thickness.

4. Masking and Protection

When engraving, materials may have the need for masking or protection in order to prevent any kind of unwanted marks on the surrounding region.

Whereas, laser cutting needs more accurate alignment and positioning to ensure that the cuts are made exactly where planned.

5. Cost

Laser engraving machines are usually more affordable when compared to laser cutting machines, which makes them easily accessible for individuals and small businesses.

Laser cutting machines are typically more expensive because they have higher power needs and precision is required for cutting thicker substances.

6. Maintenance

Laser engraving machines generally demand minimal maintenance requirements described in relation to laser cutting machines, because the surface-level engraving method is less taxing on the components of the machine.

Laser-cutting machines may need extra maintenance because of the high power levels requirement involved and the wear and tear caused by cutting through various materials.

8. Speed and Power

Laser engraving machines generally utilize lower power levels and change positions of the laser beam quickly over the material's surface to create detailed & enduring marks.

On the other hand, laser-cutting machines typically require higher power levels in order to melt or vaporize the component along the cutting path, which results in slower processing speeds.

9. Materials

Laser engraving can be conducted on a wide range of materials, such as glass, plastics, acrylic, leather, wood, ceramics, coated metals and more. This specific process functions well on substances that can be etched or vaporized, leaving an observable contrast.

On the other hand, laser cutting can be performed on a variety of substances, which include wood, fabrics, paper, acrylic, plastics, rubber, thin metals, and more. The material must be able to soak up and conduct heat for effective cutting.

10. Applications

Laser engraving is generally utilized for branding, personalization, artistic designs, and industrial applications where explicit markings or designs are needed. It is usually utilized on substances such as wood, plastic acrylic, glass, leather, and metal.

Laser cutting is broadly utilized in different industries for manufacturing parts, prototypes, signage, product packaging, and more. It can cut through a variety of materials, comprising metals, plastics, textiles, wood, paper, and foam.

What Are The Pros And Cons Of Laser Engraving Machines?

Laser engraving machines come with various advantages and disadvantages depending on the application, materials, and requirements. Let's explore the advantages and disadvantages of this specific machine!

Advantages Of Laser Engraving Machines:

Precision is one of the biggest advantages of laser engraving machines. They have the capability of engraving or etching on the most intricate designs including a wide range of materials like metal, plastic, wood, etc.

They are quite efficient and can finish off the engraving procedure rapidly with amazing accuracy. They are a highly suitable choice for businesses who are seeking to streamline their production methods.

They also offer a great level of personalization, which allows users to develop unique designs for a broader spectrum of applications.

Disadvantages Of Laser Engraving Machines:

Laser engraving machines can be costly to afford and set up, which might be an impediment for small businesses or individuals.

While laser engraving can create intricate designs, there may be a few limitations in terms of design size, complexity, and the types of fonts that can be actually engraved.

While laser engraving is versatile, there are certain materials that may not respond well to laser engraving because of their composition, reflective properties, or toxicity when burned. It's crucial to choose eligible materials for the laser engraving process.

What Are The Pros & Cons Of Laser Cutting?

Laser cutting is a versatile and precise technology utilized to cut various materials with the assistance of a focused laser beam. It finds applications in industries such as manufacturing, automotive, aerospace, electronics, and more. Here are some of the advantages and disadvantages of laser cutting:

Advantages Of Laser Cutting:

Laser-cutting machines are positively efficient in nature and are able to design patterns with high precision.

They actually require as well as consume a nominal amount of energy in order to cut sheets of different types of materials.

They are extremely flexible and can be utilized to cut almost all types of substances.

When compared to traditional forms of cutting, laser cutting machines take minimum time to cut huge sheets and the result is incredibly accurate.

The whole process is monitored by computer programs which helps in reducing the amount of work as well as workload.

Disadvantages Of Laser Cutting:

Production rate might vary depending on the type and the thickness of the material.

Inappropriate settings of laser cutting machines can result in burns.

Laser cutting machines can be more expensive when described in relation to other methods of cutting sheets.

In Conclusion

Laser engraving machines and laser cutting machines, both of them do share a common technology but their objectives, applications as well capabilities make all the difference significantly. Whether you are seeking to etch intricate patterns/designs or cut precision components, understanding all these differences is critical for choosing the perfect equipment for your project!

Both methods have considerably revolutionized industries by delivering efficient and precise ways to manipulate substances, pushing the boundaries of what's conceivable in modern manufacturing as well as customization. Whether you decide to opt for a laser engraving machine, a laser cutting machine, or a combination machine, laser technology will provide countless opportunities for innovation & ingenuity.

In case of any queries, reach out to our team today!