What Is A Fibre Laser Cutting Machine?

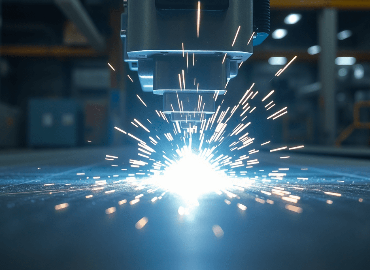

A fiber laser cutting machine is a type of laser cutting machine that makes use of a fiber laser generator as its source of light. Fibre laser cutting machines are actually a unique and amazing technique that has been created to make processes much easier. It tends to transmit a laser beam of high density and directs it to the object's surface so that the particular region is irradiated by the focused laser beam. Moreover, automatic cutting can be obtained by moving the focused laser beam via the CNC mechanical system.

Fiber laser cutting machines function in a similar way to CO2 laser cutting machines, but the light is directed via a fiber-optic cable in order to intensify the laser beam before making it aligned to the substance being cut. This actually leads to a more strong laser beam when compared to a CO2 laser source.

Fibre laser cutting machines are completely committed to providing unprecedented speed, repeatability, and precision. They are generally conformed to cutting mild & stainless steels and non-ferrous metals too. They can also be utilized for bevel and flat-cutting methods with fabulous outputs like smooth and clean edges.

Few Important Tips For Choosing A Fibre Laser Cutting Machine

Selecting the ideal fiber laser cutting machine for your work can be a daunting task at first as so many brands & models are available in the market! That's why we have come up with a list of some essential things that you should consider & will help you to narrow down your options. So, let's begin…

1) Budget

The most essential thing when it comes to buying a fiber laser cutting machine is to decide on a budget. Budget plays a crucial role in selecting the ideal machines. If you do have a sufficient budget, it's obvious that you can select a fiber laser cutting machine that is equipped with the highest configuration, has the best functions, and has a good speed. If your budget is restricted, you can decide on a cost-effective fiber laser-cutting machine to satisfy your major processing requirements.

2) Type Of Machine

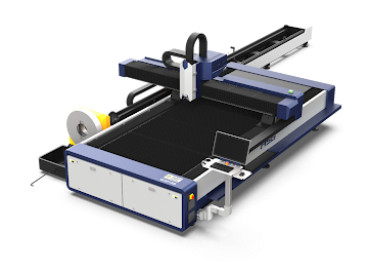

Numerous types of fiber laser cutting machines are out there which includes fiber laser cutting machine with exchange platform, metal sheet fiber laser cutting machines, fiber laser machines for cutting metal sheet and tube, metal tube fiber laser cutting machines, automatic coiling fiber laser cutter, fiber laser cutter with automatic loading and unloading, and beyond. That's the reason why you need to first specify the product requirements for your project and then go ahead with it.

3) Distinct Models

The laser manufacturing industry is filled with different modes of fiber laser cutting machines and each & every model is generally designed to function with different shapes & sizes. They also serve specific needs according to the work required! A few popular models of fiber laser cutting machines include high-power, middle sheet, flatbed, dual-use sheet, and light deploy tube. So, you need to study and do your own research about all these models to decide which fiber laser cutting machine model is more favorable for your business.

4) Part Sizes

You need to think through the part size that you will operate on to cut or engrave, and this is the deciding factor whether you require a fiber laser cutting machine to manage small or large sheets. For instance - a lot of manufacturers provide fiber laser cutters with a sheet size of about 5 feet x 5 feet. However, you can simply identify smaller laser-cutting machines if you do not wish to begin with huge sheets of metal.

And as the machine's capability to handle numerous sheets increases, so does the space that the machine occupies in your warehouse. So, if your business is into mass manufacturing and you do not have any issues regarding space crunch, then you can opt for a huge machine, otherwise, the smaller one is best suited for you!

5) Speed

As we all know, time is money and when it comes to a fiber laser cutting machine, it helps you to save a lot of time as well as it's effortless. When comparing the speed of a fiber laser cutting machine with a CO2 laser cutting machine having the same power, it indicates that the fiber laser machine is faster in this case!

Fibre laser cutting machines provide faster cutting speed which helps in improving efficiency & accuracy and hence, handle more work at the same time. It does not matter whether you require engraving or marking, the speeds provided by fiber laser cutting technology are unparalleled in the industry today.

6) Advanced Technology

Fiber laser cutting machines embody the most advanced technology that is available in the market. When compared with CO2 or crystal lasers, which have existed for decades now, it comes to be evident that the technology utilized in fiber laser cutters is more detailed and advanced.

Again, these types of machines can be efficiently utilized in various industries with utmost ease. For instance - when it comes to a CO2 laser cutter, it can be utilized for cutting through metals like aluminum or stainless steel, which can be counted as a drawback and therefore, it cannot be utilized in different industries. Whereas, there are no such deficiencies with a fiber laser cutting machine because it can function with reflective as well as non-reflective substances.

7) After-Sales Service

Lastly, one of the most important tips for selecting the ideal fiber laser cutting machine is that you should definitely look for a reputable and good laser manufacturer. Read their reviews or evaluate the services they provide to their customers after the sales process is completed. Typically, fiber laser cutting machines are widely known for less maintenance, but selecting a promising manufacturer is still a better idea!

What will you do if a specific part of your machine will not function in a proper way and you will not be able to get a solid replacement for this part? This clearly specifies why it is necessary to focus on the post-sales service of laser-cutting machine manufacturers. In order to find a great cutter manufacturer, you should ask them the questions that you have in your mind and if they offer a warranty or not! A nice manufacturer will provide superb aid and a convenient solution to your maintenance or repair necessities.

All Set To Purchase Ready A Fiber Laser Cutting Machine For Your Business?

So, was this helpful? What's next? Of course, now it's time for you to finish seeking a reputable laser cutter manufacturer! Head over to Laser Technologies, we are here to offer high-quality and world-class products. Also, despite providing the nearest quality products in the industry, we at Laser Technologies are fully dedicated to offering affordable products to our clients.

So, if you are prepared to purchase a fibre laser cutting machine for your next big project, then get in touch with us right now! If you have any queries or doubts, we are here to help you out and provide you with the best solution.