Table of Content

- What is Fiber Laser Cutting?

- What is the History of Fiber Lasers?

- How Does a Fiber Laser Cutter Work?

- What are the Materials that a Fiber Laser Machine Can Cut?

- Types of Fiber Laser Cutting Machines?

- Key Benefits of Fiber Laser Cutting Machines

- Disadvantages of Fiber Laser Cutting

- Factors to Consider When Choosing a Fiber Laser Cutting Machine

- Maintenance and Care of Fiber Laser Cutting Machines

- Difference Between Fiber Laser Cutting Machine and CO2 Laser Cutting Machine

- Why Choose Laser Technologies for Your Fiber Laser Cutting Machine?

- Conclusion

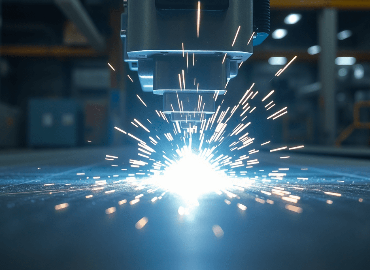

In today’s industrial landscape, fiber laser machines have become popular due to their high precision cutting capabilities and efficiency. The growing demand for high-quality, intricate metal cutting has led to the widespread use of fiber laser cutting machines. This process involves a high-powered laser beam that is generated and focused through fiber optics onto the material to be cut. These advanced machines have revolutionized manufacturing, offering better speed and accuracy.

What is Fiber Laser Cutting?

Fiber laser cutting is a process where a high-powered laser beam is directed onto a metal surface to make precise cuts. How does a fiber laser work? The laser is generated through fiber optic cables, making it much more efficient and powerful than traditional CO2 laser-cutting machines. Fiber laser cutters use a solid-state medium (fiber optic cables) to generate light, which is then amplified and focused onto the material. The material absorbs this laser energy, which causes it to heat up and vaporize, producing an accurate cut. The primary benefit of fiber lasers lies in their ability to deliver extremely fine, clean cuts at high speeds.

A fiber laser cutting machine is a type of CNC (Computer Numerical Control) machine that uses fiber-optic technology to create a focused beam of light. This beam is directed onto the surface of a material, typically metal, to cut through it. The laser's high intensity heats the material to a molten or vaporized state, which is then blown away by a gas stream, leaving a clean, precise cut.

What is the History of Fiber Lasers?

Here is a quick overview of the history of fiber lasers:

1. The 1960s - Inception of Lasers

The concept of lasers was first brought in the 1960s, with the first working laser illustrated by Theodore Maiman. A solid crystal was used as a gain medium by this laser.

2. The 1970s - Introduction of Optical Fibers

The evolution of optical fibers achieved momentum in the 1970s. Optical fibers are defined as thin strands of glass or plastic that have the ability to transmit light signals over long distances with minimal failure. This laid the foundation for the future expansion of fiber lasers.

3. 1980s - Emergence of Fiber Lasers

In the 1980s, initial research and developments were made about fiber lasers and researchers started to explore the possibility of utilizing optical fibers as the gain medium. In 1987, Elias Snitzer brought up the concept of a "fiber laser amplifier," which further laid the foundation for the development of fiber lasers.

4. The 1990s - Progress and Commercialization

Throughout the 1990s, significant progress was made in fiber laser technology. Researchers improved the efficiency and power output of fiber lasers, making them more practical for various applications. Commercialization efforts also began, and companies started producing fiber laser systems for industrial applications like marking and material processing.

5. The Early 2000s - Power Scaling and Wavelength Diversity

The early 2000s is considered a period of immediate advancement in fiber laser technology. Researchers formulated methods for power scaling, authorizing fiber lasers to produce higher output powers. Besides, improvements in rare-earth-doped fibers encouraged fiber lasers to be utilized at varied wavelengths, extending their versatility and application bandwidth.

In the past few years, research has been solely focused on pushing the limits of fiber laser enactment, comprising wavelength agility, power scaling, and beam quality improvement. In addition, progress in nonlinear optics has facilitated the generation of new wavelengths through methods such as supercontinuum generation.

How Does a Fiber Laser Cutter Work?

The operation of a fiber optic laser cutting machine involves several key components:

- Laser Source: This is where the laser light is generated. In fiber lasers, a rare-earth element like ytterbium produces the laser beam.

- Beam Delivery: The laser beam travels through a fiber-optic cable to the cutting head.

- Cutting Head: The cutting head focuses the laser beam onto the material, allowing precise cuts to be made.

- Assist Gas: An assist gas (often nitrogen, oxygen, or compressed air) is used to blow away molten material and cool the workpiece.

- CNC Control: A CNC system precisely directs the movement of the cutting head by the digital design input (G-code or CAD files) to the machine.

What are the Materials that a Fiber Laser Machine Can Cut?

A fiber laser cutting machine is known as a versatile and powerful tool that has acquired good popularity for its capability to cut through a wide range of substances with efficiency and precision. One of its primary resilience lies in its capability to cut through various metals, such as stainless steel, steel, copper, brass, aluminium, and even more specialized alloys like tool steels or nickel alloys. The focused energy of the fiber laser beam enables quick melting and evaporation of metal surfaces, which results in clean and precise cuts.

Beyond metals, fiber lasers are well-suited for working with other materials like plastics which include acrylic, polycarbonate, ABS, and PETG, these substances can be effectively cut with fiber lasers, however, optimal cutting parameters might vary on the basis of the type of plastic. This ability extends to textiles and fabrics, where fiber laser cutting machines can develop intricate patterns and designs in materials ranging from delicate fabrics to powerful leather.

Fiber lasers are also being used in cutting ceramics, although the brittle nature of ceramics needs extraordinary attention to accomplish desired outcomes. In industries like automotive and aerospace, fiber lasers are utilized to cut through fiber-reinforced composites, which merge layers of different elements like carbon fiber and epoxy resin. For electronics and microfabrication, fiber lasers excel in cutting thin films with utmost precision, contributing to the production of intricate electronic elements.

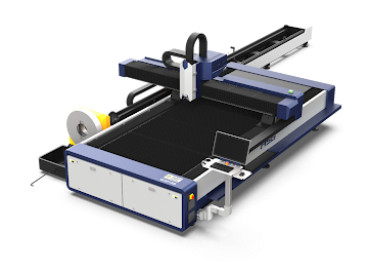

Types of Fiber Laser Cutting Machines?

Here are the three types of fiber laser cutting machines:

1. Low-Power Fiber Lasers

This type of fiber laser cutting machine is normally utilized for cutting thin substances such as metals, sheet metal, and plastics. They are typically utilized in industries like electronics, signage, and jewelry making.

2. Medium Power Fiber Lasers

These fiber laser machines are eligible for operating on a wider range of materials and thicknesses, comprising metals and alloys of medium thickness. They find applications in industries like aerospace, automotive, and machinery manufacturing.

3. High-Power Fiber Lasers:

The high-powered machines are specifically designed for heavy-duty cutting of thick metals and are generally utilized in industries needing high throughputs, such as construction, shipbuilding, and heavy machinery.

Key Benefits of Fiber Laser Cutting Machines

Some key Benefits of fiber laser cutting machines include high precision cutting, increased productivity, and reduced maintenance costs. Additionally, these machines are known for their versatility in cutting a wide range of materials with efficiency and speed.

1. Precision and Accuracy

Fiber laser cutting machines are known for their precision. A laser beam can be focused into a small point, allowing for extremely fine cuts even in thin materials. The accuracy of the cut ensures that the final product is of the highest quality, with minimal need for post-processing.

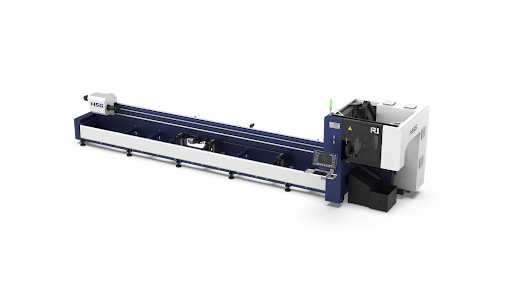

The Tiny Tube Laser Cutting Machine R1 by Laser Technologies is designed specifically for cutting small to medium-sized tubes with high precision. This model is ideal for industries that require high-quality tube cutting with minimal material wastage.

2. Higher Speed and Efficiency

Fiber laser cutting machines operate much faster than their CO2 counterparts. They can cut intricate designs in a fraction of the time, which significantly boosts productivity. The ability to cut materials at high speeds makes fiber lasers an ideal solution for industries with demanding production schedules.

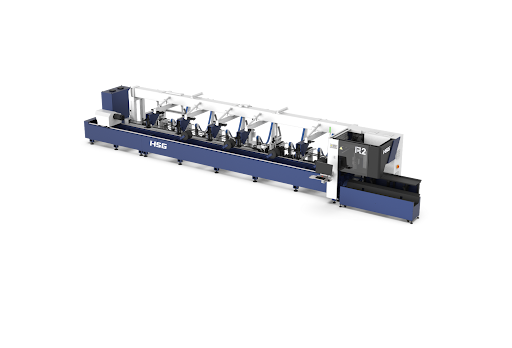

The Universal Tube Laser Cutting Machine R2 offers more versatility in tube and pipe cutting. This model is engineered to handle more complex cutting tasks with ease, ensuring high efficiency.

3. Cost-Effective Operations

Despite their high initial investment, fiber laser cutting machines tend to be more cost-effective in the long run. They have lower operational costs due to their reduced energy consumption, especially when compared to traditional CO2 lasers. Furthermore, their high cutting speeds lead to quicker turnaround times, increasing overall production output.

4. Minimal Maintenance

Fiber laser cutting machines require significantly less maintenance than other laser types. They do not have mirrors or lenses that need regular cleaning, making them low-maintenance and more reliable over extended periods.

5. Environmental Sustainability

With a lower energy consumption compared to CO2 lasers, fiber lasers are more environmentally friendly. Their compact design and efficient use of resources make them a preferred choice for industries aiming to reduce their carbon footprint.

Disadvantages of Fiber Laser Cutting

Fiber laser cutters are the most advanced equipment and are the perfect ones for various applications, but they also have their own bunch of demerits. Here are some of the disadvantages of fiber laser cutting machines:

➤ When compared to CO2 laser cutters, fiber laser cutting machines do not deliver a smooth finish as a result.

➤ Fibre laser cutting machines that are of low power do not result in good quality cutting when it comes to processing thicker metals in comparison to CO2 laser cutters.

➤ Fibre laser cutting machines and their parts are too expensive, which makes them less affordable.

However, despite having these disadvantages as a part of its operation, fiber laser cutting machines are more useful as there are a lot of advantages it has to offer! With the advancement in technology, it is possible that all the demerits will soon be addressed to improve the quality of work.

Factors to Consider When Choosing a Fiber Laser Cutting Machine

Investing in a fiber laser cutting machine is a significant decision, and selecting the right one depends on your specific needs and operational requirements.

1. Power Output

The power of a fiber laser is one of the most critical specifications and is measured in watts.

- Low Power (e.g., 500-1000W): Suitable for thin materials like sheet metal and fine details.

- Medium Power (e.g., 2000-3000W): Versatile for cutting a variety of metals like stainless steel, aluminium, and carbon steel at moderate thicknesses.

- High Power (e.g., 4000W and above): Ideal for heavy-duty industrial use, allowing you to cut thicker materials at high speeds.

Consider the types of projects you will be handling and the potential for future growth when choosing the appropriate power output.

2. Cutting Speed

The machine's power, material thickness, and type all have an impact on cutting speed and production efficiency. Higher power machines tend to cut faster, reducing cycle times. Evaluate the machine's performance across different materials and thicknesses to ensure it aligns with your production timelines.

3. Automation Features

Modern fiber laser cutting machines often include automation to streamline operations and enhance productivity.

- Material Handling Systems: Automated loading and unloading systems reduce manual labour and downtime.

- Advanced CNC Controls: Enable precise and complex cutting patterns with minimal human intervention.

- Real-Time Monitoring: Some machines come equipped with IoT capabilities for remote monitoring and diagnostics.

Automation can significantly improve throughput and operational efficiency, especially in high-volume production environments.

4. Machine Size and Workspace Considerations

The size of the machine should fit your workshop or factory layout while accommodating your material dimensions:

- Bed Size: Choose a bed size that matches the largest material sheets you plan to cut.

- Footprint: Ensure there is adequate space for the machine, auxiliary equipment, and safe operation.

5. Maintenance and Operating Costs

Factor in the long-term costs, including:

- Maintenance Requirements: Regular servicing, cleaning, and component replacements.

- Energy Efficiency: Machines with advanced power management features can lower electricity costs.

6. Brand Reputation and Support

Choose a reliable manufacturer or supplier with a proven track record. Consider:

- Availability of spare parts.

- Warranty and after-sales support.

- Training programs for operators and maintenance personnel.

7. Budget and ROI

Finally, balance your budget with the expected return on investment (ROI). While high-end machines may have a larger upfront cost, they often offer better efficiency, longevity, and precision, ultimately saving money in the long run.

By thoroughly evaluating these factors, you can make an informed decision that ensures the chosen fiber laser cutting machine meets your production needs, maximises efficiency, and supports future growth.

Maintenance and Care of Fiber Laser Cutting Machines

To ensure the longevity and performance of your fiber laser cutting machine or CNC laser machine, regular maintenance is crucial. Key maintenance tasks include:

- Lens Cleaning: Keep the lens of the laser cutting head clean to ensure optimal focus and performance.

- Gas Pressure Checks: Ensure the assist gas is being used at the correct pressure and flow rate.

- Cooling System: Check the cooling system regularly to prevent overheating, especially in high-demand operations.

- Software Updates: Keep the machine's software up-to-date for smooth operation and access to the latest features.

Difference Between Fiber Laser Cutting Machine and CO2 Laser Cutting Machine

Fiber laser cutters and CO2 laser cutters differ from each other as they are both utilized for different purposes. We have mentioned some of the common differences below, check it out:

- Wavelength

Fibre laser produces a shorter wavelength when compared to CO2 laser cutting machines. That is why fiber lasers have great absorption power which helps in enhancing the cutting quality and speed.

- Different Mechanisms Used

Fibre laser cutting machines utilize components such as neodymium, erbium, dysprosium, and yttrium. Combining these elements produces a crystalline solid as a fiber, and then this is directed into the cutting head of the machine via a transport fiber. On the other hand, CO2 lasers utilize carbon dioxide, helium, nitrogen, and various other gases. All these gasses are mixed together to generate a focused laser beam.

- Efficiency

As the fiber laser cutting machine is able to quickly process the operation with enough proficiency, it gives out financial advantages when it comes to high-volume manufacturing. Moreover, CO2 laser cutting machines require a warm-up time before starting with the process, which helps in reducing efficiency as well as output.

- Material

Fiber laser cutting machines are suitable for cutting sheet metals whereas for thick plate cutting, CO2 laser cutting machines are perfect.

Why Choose Laser Technologies for Your Fiber Laser Cutting Machine?

Laser Technologies offers fiber laser-cutting machines that cater to a variety of manufacturing needs. With a focus on precision, performance, and innovation, Laser Technologies ensures that each product is built with quality.

1. Custom Solutions for Every Industry

Laser Technologies provides tailored solutions to meet the unique requirements of different industries. Whether you need a compact machine for small tube cutting or a versatile machine for large-scale production, Laser Technologies offers products that align with your business needs.

Naman Industries relied on Laser Technologies for a high-stakes project, requiring advanced capabilities beyond their existing infrastructure. The team at Laser Technologies promptly identified the ideal machine and dispatched it the next day, ensuring project success and client satisfaction.

2. World-Class After-Sales Support

One of the standout features of Laser Technologies is its exceptional after-sales support. With a dedicated team of experts ready to assist you, customers can rely on Laser Technologies for regular maintenance, troubleshooting, and advice on optimizing machine performance. The company also offers training services to ensure your team gets the most out of the equipment.

3. Cost-Effective Solutions

While Laser Technologies fiber laser cutting machines come with advanced features, they also offer cost-effective pricing structures. This guarantees that manufacturers, ranging from small businesses to large enterprises, can reap the benefits of high-performance cutting solutions without incurring significant costs.

Praveen Weld was looking for a laser welding machine that was expensive, and beyond their budget. Then Laser Technologies offered them with Germany-based Alpha Lasers Fiber cutting machine which was in their budget. The laser welding machine was top-of-the-line and beyond their expectations.

Also Read, Latest Innovations in Fiber Laser Cutting Technology - Power

Conclusion

Fiber laser cutting machines or CNC fiber laser cutting machines are a cornerstone of modern manufacturing, offering unmatched precision, speed, and efficiency. Whether you’re cutting tubes, sheets, or custom components, fiber lasers provide the accuracy and flexibility that today’s industries demand.

Laser Technologies offers exceptional after-sales support and commitment to quality. Invest in the future of manufacturing today, and unlock the potential of fiber laser technology with Laser Technologies.