AHS

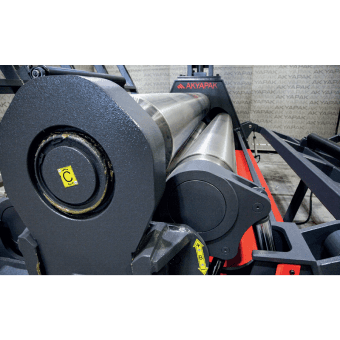

4-Roll Plate Rolling Machines

Great Solutions For Great Challenges

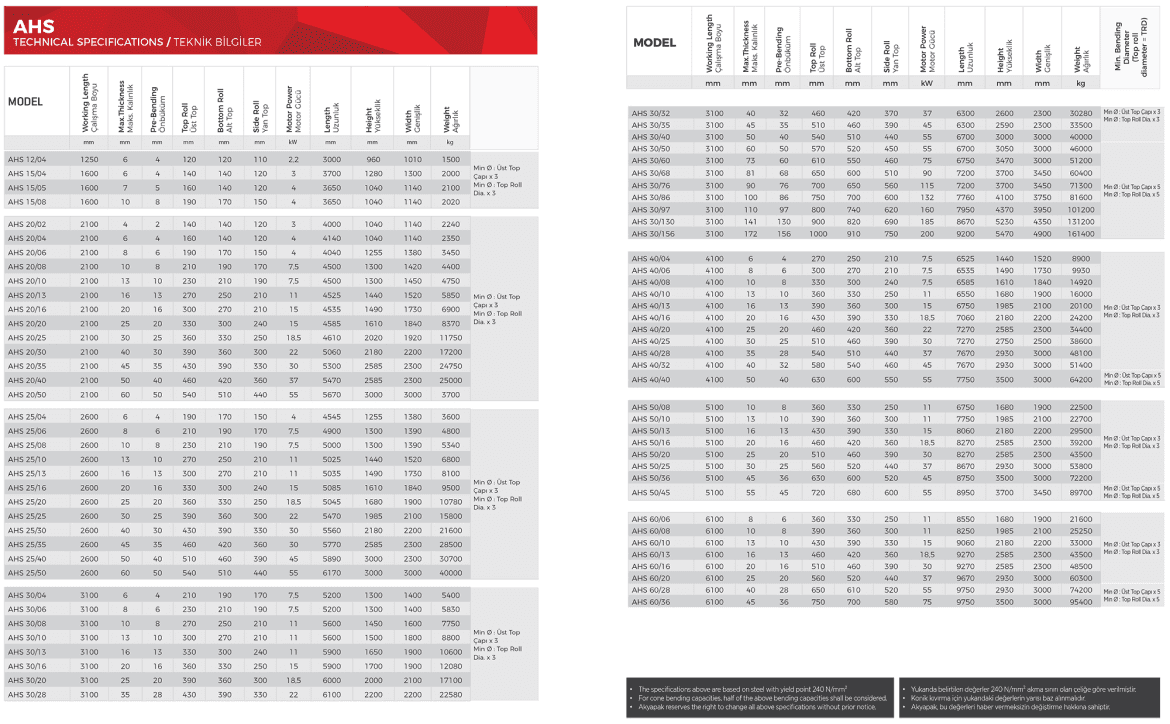

Akyapak’s 4-roll AHS model offers reliable and excellent solutions for precise and challenging rolling applications. It is the most reasonable choice to bend the materials with a plate thickness of 2 mm to 200 mm and with a plate width of 500 mm to 12000 mm.

Prescide, Productive and Reliable

As well as being reliable, AHS increases productivity with its high speed rolling ability and it overcomes the most challenging bends thanks to its ease of use. Since the plate is pinched during rolling, skidding and slipping of materials are prevented. Thus, more reliable rolling operations are performed and more precise results are achieved. In AHS 4-Roll Plate Rolling Machines, one of the side rolls can be used as a squaring roll, thus the plate can be easily and precisely aligned along the roll across the input direction.

Less Flat Ends At a Single Pass

It is possible to achieve a full cylinder at a single pass with AHS 4-Roll Machines, because the material can be pinched with the lower-roll during pre-bending and bending. AHS model allows for precise pinching of the plate between upper and lower rolls, thus the length of flat ends are minimized. Akyapak 4-Roll CNC Rolling Machines having superior features decrease the dependency on an operator and offer more reliable and more productive solutions.

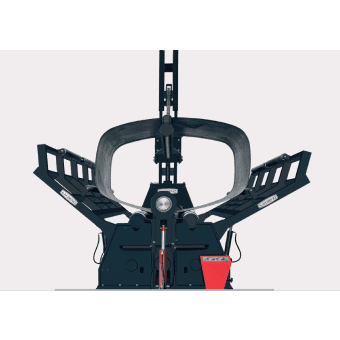

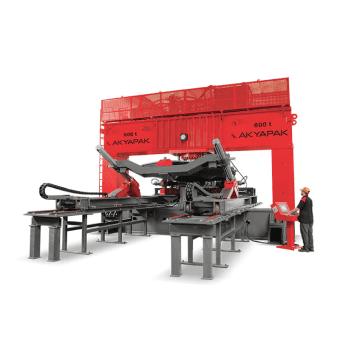

AHS-RK

Akyapak offers special solutions for wind energy industry with AHS-RK Wind Tower Bending Line it developed. With its 55 years of experience and engineering and production expertise in many product groups, Akyapak is distinguished from its competitors in the market when it comes to offering integrated solutions.

Akyapak designs the Wind Tower Bending Lines in an integrated way through the Welding Solutions it develops and produces. Akyapak Wind Tower Bending Lines that can be integrated with Column-Boom Systems and Rotators increase your productivity and provide high production capacity through high speed and automation it provides.

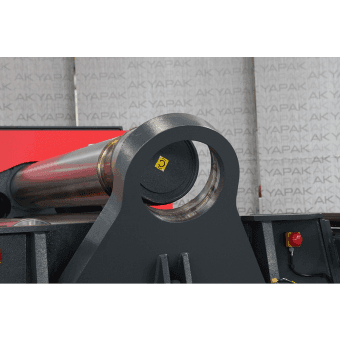

AHS-T

AHS-T Tank Bending Machine is designed with Akyapak’s 55 years of experience and engineering expertise. AHS-T easily performs the bending of tanks containing multi-radius at one pass. Akyapak, continuously improving technological infrastructure of the machines it produces, offers fast and reliable solutions for the production of long tanks through AHS-T with superior CNC features.

The diameters of rolls in AHS-T machine are small and supports are placed for preventing all the rolls from deflecting. AHS-T which can be produced in different dimensions for various applications reflects the expertise of Akyapak in “tailor-made” solutions.

AHS-PM

One of the special solutions that Akyapak offers for the specific needs of the industry, AHS-PM is designed to deliver high performance for long pipes with relatively narrow diameters.

In AHS-PM model that provides high productivity in pipe production, the top roll is designed as pre-stressed in order to compensate deflections. The top roll can be changed very fast for various pipe diameters and thicknesses.

AHS-V

AHS-V Vertical Plate Rolling Machine is an ideal solution for rolling in wide diameters or in a half-cylinder form. AHS-V which is another solution of Akyapak for the specific needs of the industry requires less space with its vertical design.

- Cone rolling device

- Induction hardened rolls

- Digital readout for side rolls

- Fully welded steel (St-52) frame

- Separate moveable control panel

- Dual bending speeds

- All rolls are mounted in spherical roller bearings

- Hydraulically opened/closed drop end controlled from control panel

- Activation of cone rolling function and position adjustment via buttons on the control panel

- Top and bottom rolls (central rolls) driven by hydraulic motors and planetary gear reducers

- Electro – hydraulic calibration

- CE, ISO9001 – 2015, TSEK ve TURQUM certifications

- Variable speed of rotation

- Material feeding table

- Oil air cooler

- Central support

- Side supports

- Material ejector

- Interchangeable top roll

- NC AK300

- CNC AK400

Photo Gallery

Request Detail Information

Please fill out the requested information and you will be contacted soon.

Fill out the form to get a free consultation.