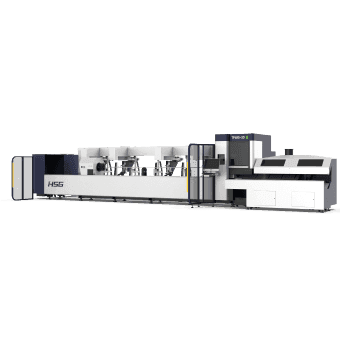

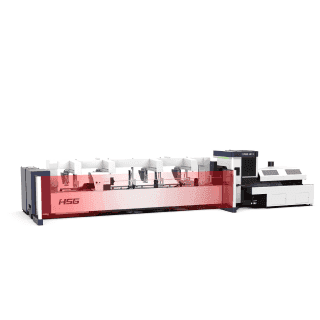

TP65S Series

TP65S Series Professional Bevel Tube Laser Cutting Machine (1500-4000W)

- Joggling database for nearly 100 kinds of tubes

- Lubricates automatically

- Tube processing assistance

- Remind to maintain machine bed after expiration

TP65S Series Professional Bevel Tube Laser Cutting Machine (1500-4000W)

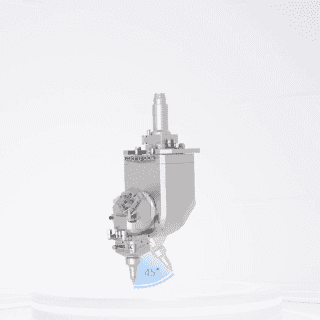

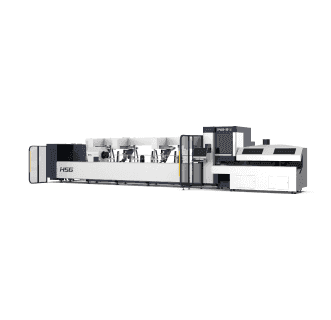

HSG’s five-axis linkage CNC technology makes 45° bevel cutting possible and allows mass production of tubes, which is usually applied to cutting medium-to-thick tubes into bevels. The unique RapidCut technology, with rapid three-axis line interpolation, has improved production efficiency by 30% than general X and Y-axis interpolation.

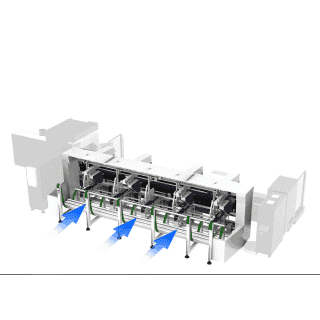

Intelligentization: claw status is detected in real time and tube data are easily accessed. Due to closed-loop control, it is safe and reliable for users; clamping force is under self-adaptive control, as thus, small tubes will remain unchanged and large tubes are clamped stably; Full stroke: no need for changing claws while clamping Φ20-254mm tubes, reducing the non-productive duration; Wide range of cutting: round tube dia. Φ20-254mm, square tube (side length) 20*20-200*200mm, also cut profiles like channel and angle steel, and special-shaped tubes. Max. weight of a single tube: 200kg.

X9500 is the fourth generation control system self-developed by HSG Laser. Based on previous upgrades, it becomes more stable and can intelligently detect tube deformation and compensate for graph offsets automatically. With extremely simple UI design, X9500 shows air pressure, power, speed and tube graphs on its screen and takes integrated control of automatic loading & unloading, chucks and supporting brackets.

The patented technologies will help to minimise the moving path of the cutting head by omitting repeated lifting and falling, and cutting efficiency is improved by 50%+ especially while cutting square tubes.

| Feature/Model | TP65S |

|---|---|

| Round Tube Processing Dim | Φ20-Φ273mm |

| Square Tube Processing Dim | 20*20mm-200*200mm |

| Rectangle Tube Processing Dim. | Diagonal≤254mm |

| Profile Processing | Yes |

| Max Single Tube Loading Weight | 200kg |

| Max Bundle Loading Weight | 300kg |

| Chuck Type | Pneumatic chuck |

| Chuck Max. Loading Weight | 200kg |

| Chuck Rotating Speed | 120r/min |

| Max. Moving Speed | 140m/min |

| Max. Acc. Speed | 1.2G |

| Max. Length of Cutting Tube | 650mm |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Laser Power | 1.5KW~4KW |

| Overall Dimensions (L*W*H) | 12500×3000×2600mm |

| Overall Dimensions (L*W*H) loading structure incl. | 12500×4700×2600mm |