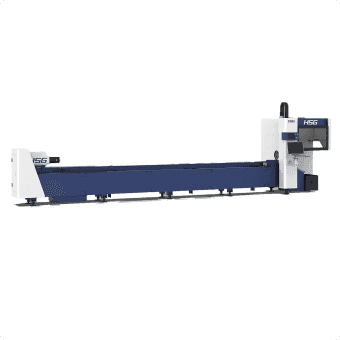

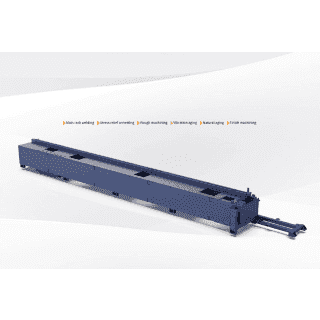

TM65/TM65II

Tiny Tube laser cutting machine (1500-3000W)

- Min diameter of tube 10mm

- Max weight of a single tube 50kg

- Flying Cutting and Cross-plane leapfrog

- HSG-X9000 Bus Control System

Tiny Tube laser cutting machine (1500-3000W)

TM65 II is intended for furniture and other small tube cutting industries. As the second generation, it has a wider range of cutting and shorter tailing than the first. Its remarkable dynamic performance lies in its max. rotating speed of chucks 150r/min, max. no-load speed 120m/min and max. acceleration 1.0G.

The front and rear chucks are featured by automatic centering and dual-driven rotation, keeping them synchronous, therein, front chuck is full-stroke and cutting tailing is further shortened to 50mm by front chuck avoidance cutting.

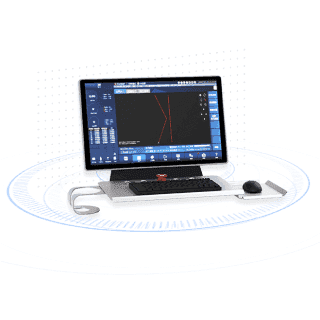

X9000, based on the German CNC bus control system, is compatible with conventional tubes and various profiles. With rich auxiliary functions, such as tube error detection and welds check, X9000 can make laser cutting simple, automatic and intelligent.

Its main body, welded by steelwork, is a heavy-duty rack. In view of high-speed movement, the machine bed is specially designed as reinforced type. After two aging treatments, it can keep high precision and stability under high acceleration.

The industry’s unique patented technologies (No. ZL201810158585.8), namely, flying cutting and cross-plane leapfrog cutting help to avoid cutting head from repeated lifting and falling. The cutting efficiency will be improved by 50%+ especially while cutting square tubes.

| Feature/Model | TM65 | TM65 II |

| Round Tube Processing Dim. | Φ10-Φ100mm | Φ10-Φ160mm |

| Square Tube Processing Dim. | 10*10mm-70*70mm | 10*10mm-70*70mm |

| Rectangle Tube Processing Dim. | Rectangular tube: diagonal≤135mm | Rectangular tube: diagonal≤135mm |

| Laser Power | 1500-3000W | 1500-3000W |

| Max. Rotating Speed of Chucks | 170r/min | 150r/min |

| Max. No-load Speed | 140m/min | 120m/min |

| Max. Acc. Speed | 1.2G | 1.0G |

| Max. Length of Cutting Tube | 6000mm | 6000mm |

| X/Y Axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| X/Y Axis Repositioning Accuracy | ±0.03mm | ±0.03mm |

| Max. Weight of Single Tube | 50kg | 50kg |

| Overall Dimensions (L*W*H) | 12500*2900*2400mm | 9300*2200*2600mm |