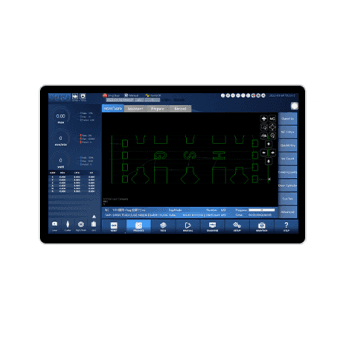

TL500 Series

An ultra-heavy Tube Laser Cutting Machine (6000W - 12000W)

This Product is unavailable.

Download Brochure

This Product is unavailable.

Download Brochure

The machine has four pneumatic chucks with big clamping force to clamp ultra-heavy tubes easily and stably.

* Bus refers to data transmission mode via the on-site bus control system.

The Servo motor adopted contains an absolute encoder to offer a power-off cutting restart function.

Our machine bed, with three sections, is easy to install and transport. After coaxial processing, these sections will be at the same precision.

It needs to be operated by 1 worker while loading a heavy tube.

Loading is in sync with unloading, without any unnecessary shutdown and tubes will not collide with each other, preventing deformation