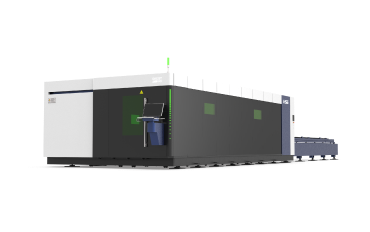

GT Pro Series

A high-power laser cutting machine (12000W - 30000W)

This Product is unavailable.

Download Brochure

This Product is unavailable.

Download Brochure

The system can make data transmission via a network cable.

* Bus refers to data transmission mode via the on-site bus control system.

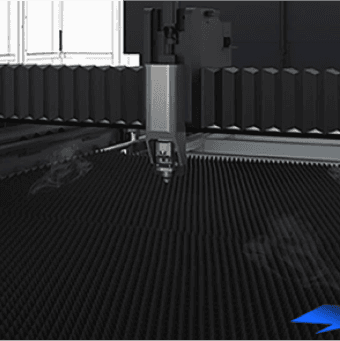

The cutting head can change its laser spot to the proper size and shape according to cutting materials and thickness.

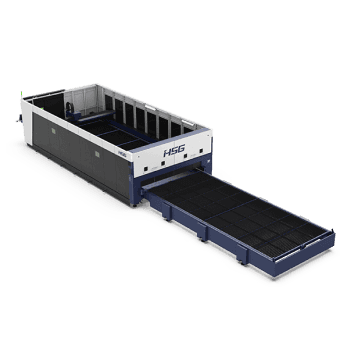

Divide the cutting area into left and right zones, outfitted with butterfly valve dampers and 300*300mm full-hollow ventilating ducts

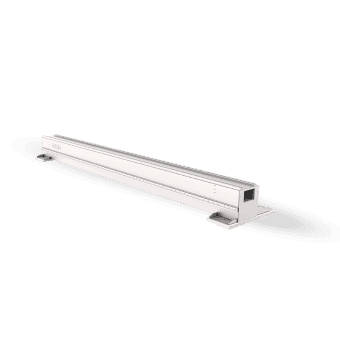

Our aluminium alloy is adopted. The aluminium beam is designed as a honeycomb anti-compression structure and made by using an extrusion molding process.