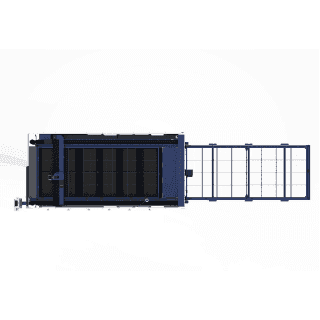

GT PRO II Series

Intelligent full-protective laser cutting machine (8000-12000W)

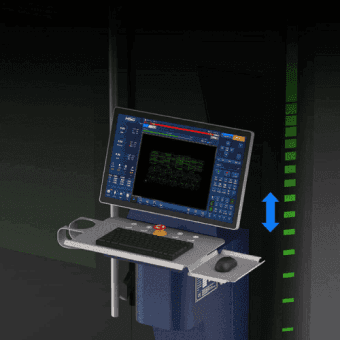

- Alpha T Bus CNC System

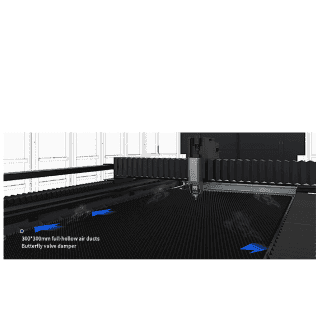

- Eco-friendly Cutting

- Dual-motor driven exchange platform (6000* 2500 nm or above formats)

- Conform to EN ISO12100, EN 60204-1, EN ISO11553

Intelligent full-protective laser cutting machine (8000-12000W)

Alpha T, self-developed by HSG LASER, can make data transmission rapid, stable and accurate only via a network cable as a technically advanced bus system.

With zoning ventilation, butterfly valve and 300*300mm full-hollow air ducts, the much better ventilation and almost smoke-free effects will come true.

Optional Features:

The double exchange platforms are driven by double motors (for 6000*2500mm or larger processing formats) stably at fast speed , which will work independently with no effect on each other. Taper pins are used for positioning the platforms to keep positioning precision within 0.5mm.

Optional Features:

Keep high precision and stability for 20+ years due to 500 Mpa tensile strength and welding stress elimination by annealing and vibration aging; Covered with military-level anti-burning manganese steel plate

The electric cabinet is integrated with the machine body to cover a small area, wherein, its standard wiring and fully-sealed structure can prevent dust entry and any possible ignition.

| Feature/Model | G4020T Pro | G6025T Pro | G8025T Pro |

|---|---|---|---|

| Working Area (L*W) | 4000mm*2000mm | 6000mm*2500mm | 8000mm*2500mm |

| Stroke (X/ Y/ Z Axis) | 2050mm/4050mm/320mm | 2550mm/6050mm/320mm | 2550mm/8050mm/320mm |

| X/Y Axis Repositioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| X/Y Axis Repositioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Max Moving Speed | 140m/min | 120m/min | 120m/min |

| Max. Acc. Speed | 1.5G | 1.5G | 1.5G |

| Laser Power | 8KW~12KW | 8KW~12KW | 8KW~12KW |

| Max. Loading Weight | 2000kg | 3500kg | 4680kg |

| Overall Dimensions (L*W*H) | 11400×3600×2370mm | 15900×4150×2370mm | 20100×4150×2370mm |