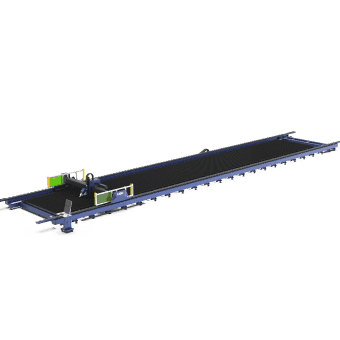

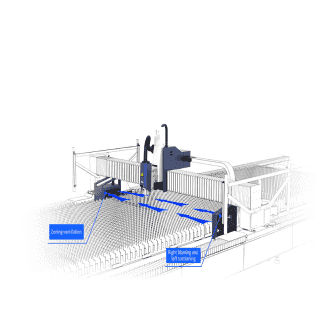

GF-B Series

Large format 3D five-axis Bevel laser cutting machine (6-30kW)

- Easy to offer, mirror like surface cutting

- Cuts sheets at higher efficiency and saves gas

- Gives early warning if abnormal

- Simple to maintain at lower costs

Large format 3D five-axis Bevel laser cutting machine (6-30kW)

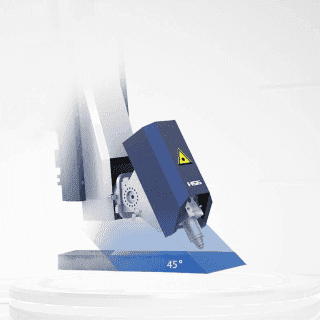

Our self-developed high-power laser cutting heads work with FANUC 3D five-axis control system to break through conventional 0° straight section and make 45° bevel possible. V-, X- and Y-shaped bevel can take shape only once, which helps to reduce working procedures and enhance cutting efficiency.

Thickness of long-term batch stable cutting: 20mm+, extreme thickness: 100mm Max. processing format 24000*5000mm, allow customization of format length Cut both sheet metals and large-sized profile steel.

The four kinds of self-developed laser cutting heads, covering medium-to-high power, high-power and ultra-high power, can cut thick metal sheets stably under high temperature, high pressure and high speed.

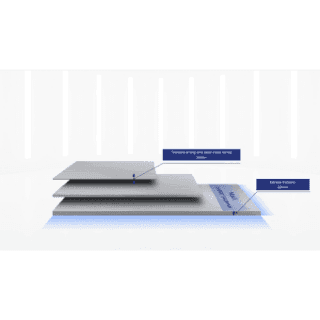

Module-based platform patented (No. ZL201921441366.7) and self-developed by HSG is easy to be dismantled and installed, without any effect on production. Our machine bed is apart from the platform to cut off the generated high-temperature heat, keep batch cutting stable, prolong service life and ensure its high dynamic performance.

With it, cutting smoke dust is blown to one side from another side of the machine bed and sucked into the special air ducts under the support of the right ventilation system. The machine bed is divided into small zones and corresponding air dampers will be opened according to cutting head position, so as to offer intensive suction.

| Feature/Model | G12032FB | G13025FB |

|---|---|---|

| Working Area (L*W) | 3200mm/12000mm/200mm | 13000mm*2500mm |

| Stroke (X/ Y/ Z Axis) | 2550mm/6100mm/270mm | 2500mm/13000mm/200mm |

| X/Y Axis Positioning Accuracy | ±0.05mm/m | ±0.05mm/m |

| X/Y Axis Repositioning Accuracy | ±0.05mm | ±0.05mm |

| Max. Moving Speed | 80m/min | 80m/min |

| Max. Acc. Speed | 0.5G | 0.5G |

| Laser Power | 8KW~30KW | 8KW~30KW |

| Max. Loading Weight of Platform | 14900kg | 12600kg |

| Overall Dimensions (L*W*H) | 19000mm*5700mm*2200mm | 20000mm*5000mm*2200mm |