GE IV Series

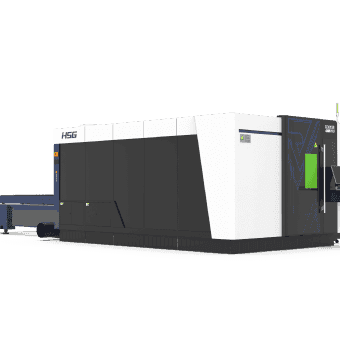

Double exchange platforms Sheet & Tube laser cutting machine (3000-6000W)

- One machine; Two functions

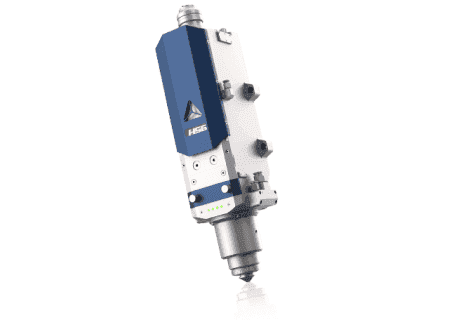

- Alpha A CNC System, self-developed by HSG

- Double exchange platforms

- First-rate core components

Double exchange platforms Sheet & Tube laser cutting machine (3000-6000W)

GE IV can cut both sheet and tube metals, replacing a professional sheet laser cutting machine and tube laser cutting machine in total. For users, it will expand their scope of cutting materials and enhance their market competitiveness.

Developed by HSG LASER, the GB series comprises Alpha A CNC System that is easy to operate even by green hands. Match with 2000+ process data on its graphical programming interface. It is compatible with multiple graphic files, incl. DXF, DWG, PLT, NC code, IGS (tube cutting). The GB series improves stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts.

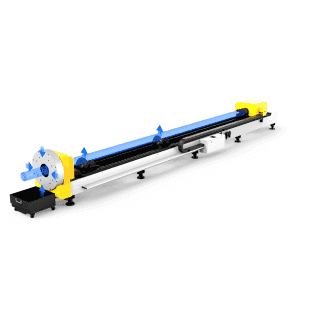

The chucks are 3 times faster than electric chucks due to one-key clamping and auto centering. With large and constant clamping force, heavy tubes will be clamping stably. Due to dual-driven pattern, the front and rear chucks can rotate synchronously.

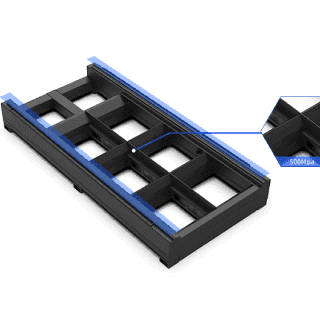

16A wide chains are adopted to enable fast exchange of platforms.

With high-precision CNC, the whole exchange will be shown on PLC touch screen.

The platforms are positioned by taper pins, in this way, its accuracy is relatively high.

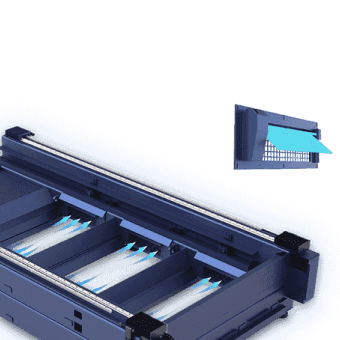

Pneumatic door between exchange platforms: prevent cutting smoke diffusion and keep working environment clean Safety light curtain: halt the machine instantly while detecting any intruder to protect machine and workers.

The zoning ventilation, butterfly valve dampers and 300*300mm air ducts can result in fast smoke discharge.

Optional Features:

| Feature/Model | G4020E-22EQ | G6020E-22EQ | G6025E-22EQ |

|---|---|---|---|

| Working Area (L*W) | 4000mm*2000mm | 6000mm*2000mm | 6000mm*2500mm |

| Stroke (X/ Y/ Z Axis) | 2025mm/4025mm/270mm | 2025mm/6025mm/270mm | 2525mm/6025mm/300mm |

| X/Y Axis Positioning Accuracy | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m |

| X/Y Axis Repositioning Accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| Max. Moving Speed | 60m/min | 60m/min | 60m/min |

| Max. Acc. Speed | 0.5G | 0.5G | 0.5G |

| Round Tube Processing Dim. | Φ20 - Φ210mm | Φ20 - Φ210mm | Φ20 - Φ210mm |

| Square Tube Processing Dim. | 20*20mm - 150*150mm | 20*20mm - 150*150mm | 20*20mm - 150*150mm |

| Laser Power | 3000W~6000W | 3000W~6000W | 3000W~6000W |

| Max. Loading of Sheet | 1400kg | 2000kg | 2500kg |

| Max. Loading of Tube | 100kg | 100kg | 100kg |

| Overall Dimensions (L*W*H) | 10950×4320×2250mm | 15500×4320×2250mm | 15500×4900×2250mm |