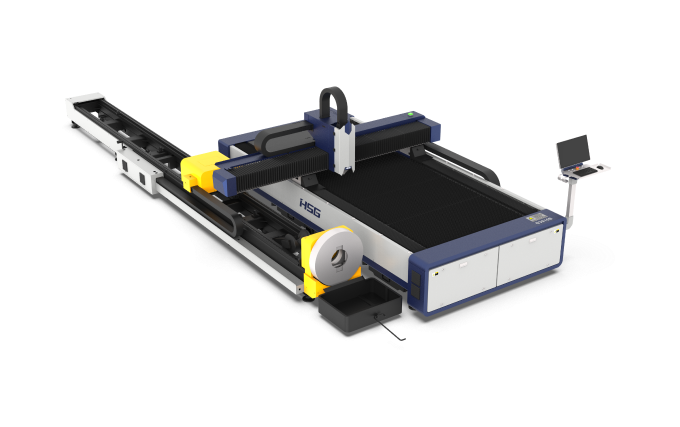

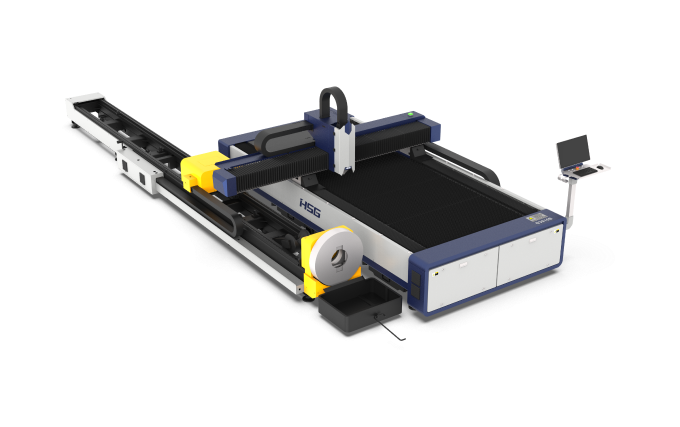

GB Series

A compact Single Platform Sheet & Tube laser cutting machine (1500W - 6000W)

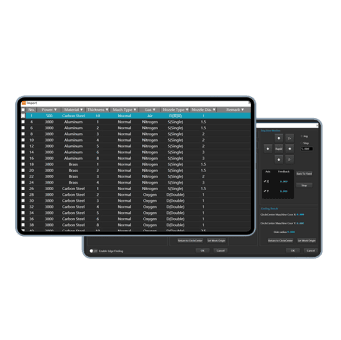

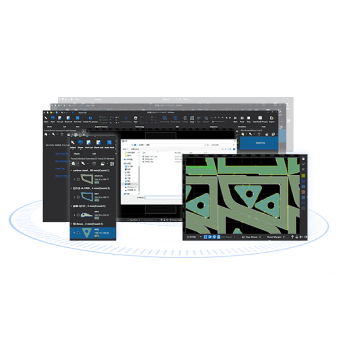

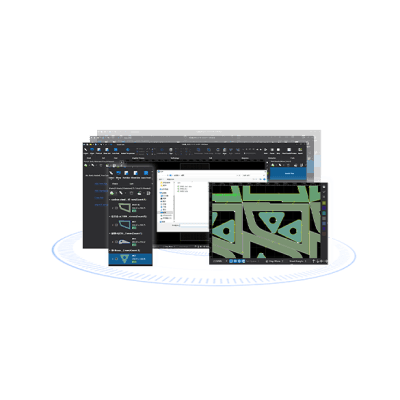

HSG-NEST works as a standalone and network-free software. In this process, Nesting will start instantly after inputting parts graphics, message and sheet size. Relevant machining reports are also available to be output.

* HSG-NEST is a standard configuration for 4000W+ models and optional for machines below 4000W.

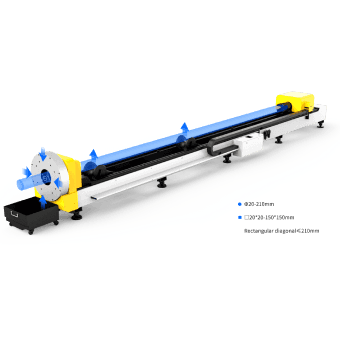

The chucks are featured by wireless control, one-key clamping and auto centering. The clamping force remains constant to clamp the heavy tube tightly. Concave supports are also adopted to prop up tubes.