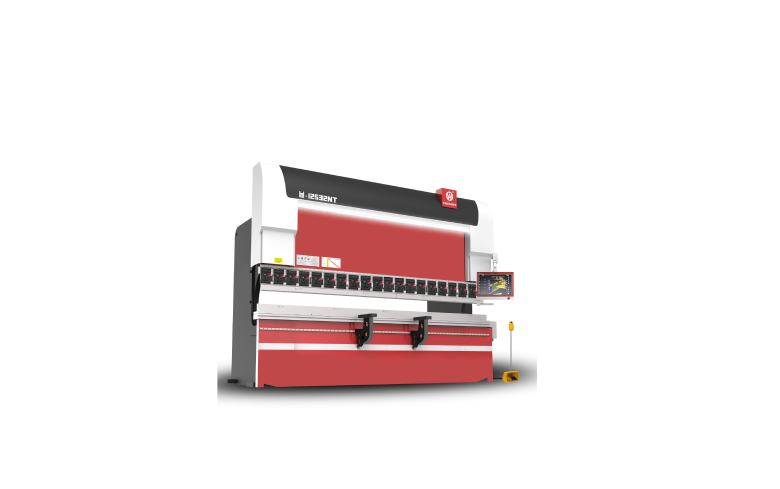

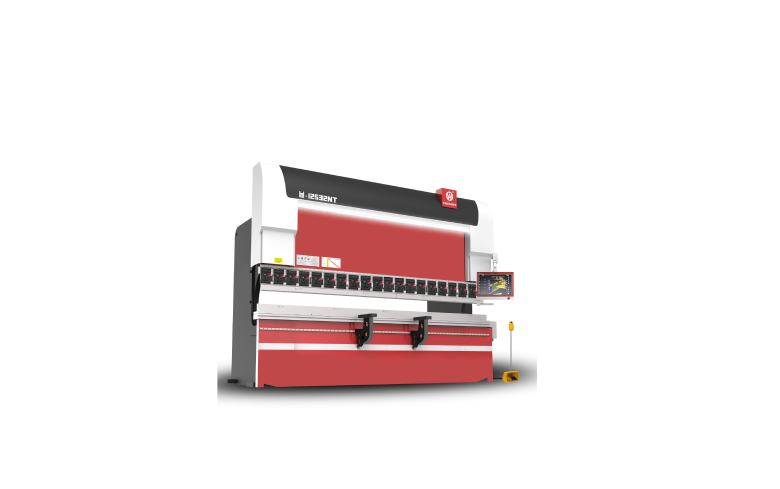

Down-Stroke CNC Press Brake

Large size, thick plate bending solution

The frame is welded by automatic welding equipment, and the welding seam is uniform, which makes the frame harder to deform under stress.

GHBM tandem press brake is good at processing super-long workpieces such as lamp posts and traffic light poles. The tandem press brake consists of two independent machines and they can run in tandem or independently.

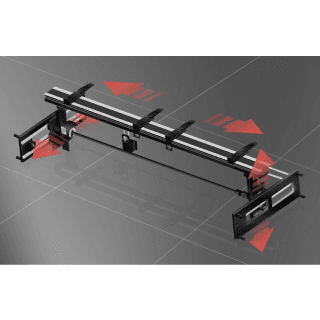

The X-axis (forward and backwards) running speed of the back gauge can reach 350mm/s, and the repeat positioning accuracy is ≤0.05mm. The stop finger is guided by double linear guides, which are more stable.

Intelligent control system with extremely simple operation, allowing users to view all parameters on one clear page.

Automatic mechanical deflection compensation technology enhances the straightness of the workpiece and accuracy of the bending angle. The CNC controller automatically calculates the compensation value, with motorized adjustments for efficiency and longer service life due to the mechanical wedge design.

Large-size colour touch screen enhances operation and viewing experience. Hardware and software are meticulously matched for seamless coordination, improving overall machine performance. The CNC controller supports multiple languages.

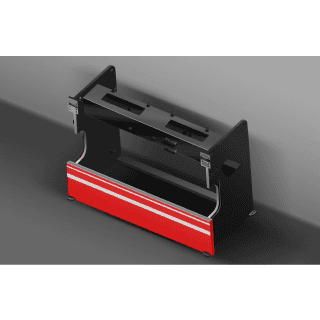

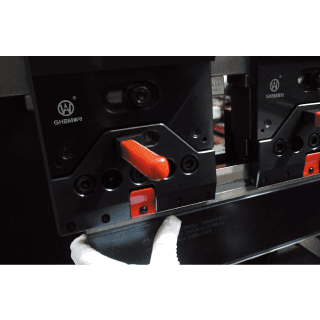

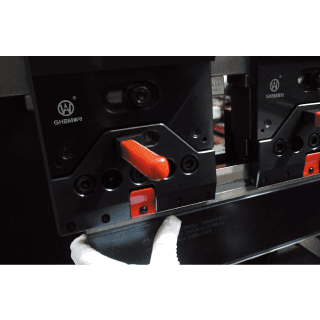

The machine has a quick-release design. You can quickly remove and install the bending mold through the quick-release clamp saving you time.

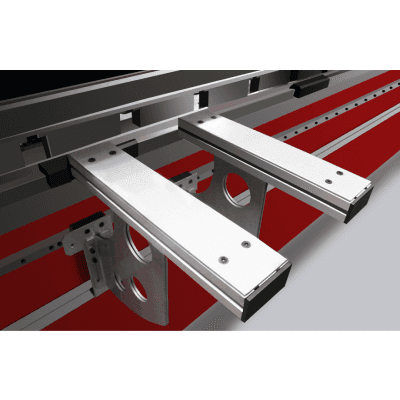

The front support device can slide left and right along the linear guide rail to provide strong support for large-size sheets.

Lightens the bending operation area and enhances the work experience of the bending operator. The use of LED light strips has low power consumption, low heat generation, long life and higher brightness.

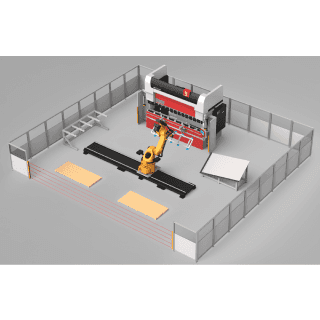

The machine provides a customized automatic bending unit, and a robotic arm automatically works with the bending liberating manpower.

The machine effectively prevents the bending mold’s clamping hands. When the upper and lower molds are clamped, if a foreign object is under the knife mold, the RAM stops moving and the machine will trigger an alarm..

| Max. Pressure | 1600 KN | Dimension (Length) | 3450 mm |

|---|---|---|---|

| Ram Stroke | 200 mm | Dimension (Depth) | 1800 mm |

| CNC Axes | Y1 / Y2 / X / R / V 4+1 | Dimension (Height) | 2750 mm |

| Main Motor Power | 15 KW | Bending Length | 3200 mm |

| Ram Approach Speed | 150 mm/s | Width Between Columns | 2750 mm |

| Ram Working Speed | 10 mm/s | Opening Height | 460 mm |

| Ram Return Speed | 130 mm/s | Throat Depth | 400 mm |

| X Axis Max. Speed | 350 mm/s | Weight | 10000 Kg |

| X Axis Range | 600 mm | ||

| Additional Notes: | |||

| Y1, Y2 Axis: Ram's up & down motion | |||

| R Axis: Back gauge's up & down motion | |||

| X Axis: Back gauge's backward and front motion | |||

| V Axis: Auto crowning (mechanical) | |||

Remark: Subject to alteration. Only specifications in the offer and order confirmation are binding.