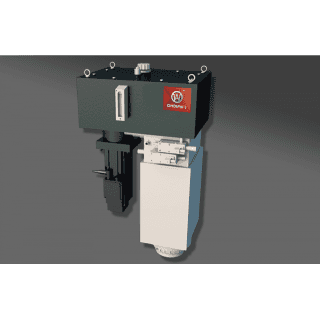

Pump Control CNC Press Brake

Fuel-saver, energy-efficient laser machine

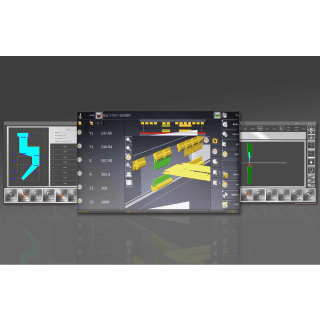

15.6-inch LCD capacitive screen with precise touch control offers a valuable interactive programming experience. It features efficient control algorithms to optimize the machine's working cycle, enabling simultaneous production of more workpieces.

The frame, processed by a large gantry machining center, is precise, stable, and durable. Equipped with safety fences on the side and rear of the fuselage and an additional mold compartment on the side.

The frame is welded by automatic welding equipment, ensuring uniform welding seams and making the frame more resistant to deformation under stress.

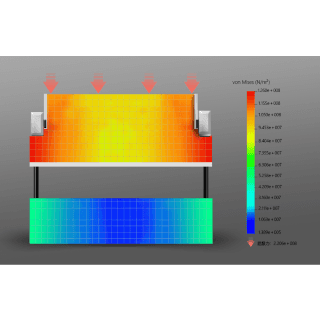

The frame is subjected to vibration ageing treatment to eliminate stress after welding. Finally, the overall rigidity of the frame is enhanced so that it can withstand long-term workloads. Self-developed back gauge mechanism

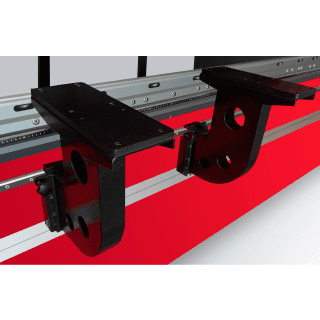

Has a number of patent designs. A number of improvements have been made to fit the user's actual use situation to make bending positioning more convenient. The imported screw rod and double linear guide rail design ensure the positioning accuracy and durability of the back gauge.

Automatic mechanical deflection compensation technology is used to effectively improve the straightness of the workpiece and the accuracy of the bending angle. The compensation value is automatically calculated by the CNC controller, and the motor is electrically adjusted, saving time and effort; the mechanical wedge design has a longer service life!

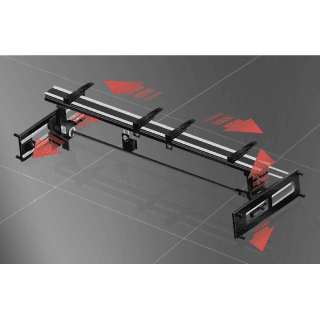

The front supporting device can move left and right along the linear guide rail and the height of the supporting material can be adjusted. It provides strong support when processing large size plates..

Has a number of patent designs. A number of improvements have been made to fit the user's actual use situation to make bending positioning more convenient. The imported screw rod and double linear guide rail design ensure the positioning accuracy and durability of the back gauge.

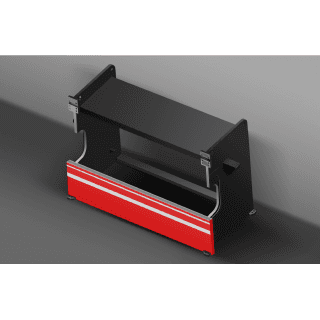

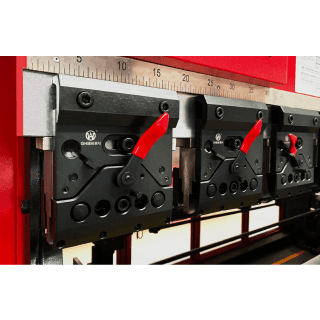

Quickly released clamp, elegant and practical design lead to better user experience.

The mold can be installed on both sides quickly, which is suitable for processing various complex workpieces and saving mold costs.

Reasonable work lighting design enables the optical fibers to be concentrated in the processing area, effectively improving the brightness of the processing area, and bringing a comfortable perating experience to the bending operator.

Dangerous areas on the back and sides of the fuselage are isolated by safety shields. And additional mold compartments on the side of the machine.

The quick-response laser protection device effectively avoids accidents of pinching hands. Ensure the safety of operators and improve the safety of production management.

| Max. Workong Pressure | 1200 KN | Ram Approach Speed | 250 mm/s |

|---|---|---|---|

| Max.Bending Length | 3200 mm | Ram Working Speed | 10-15 mm/s |

| CNC Axes | Y1 / Y2 / X / R / V / Z1 / Z2 | Ram Return Speed | 250 mm/s |

| Hydraulic Cylinder Capacity | 33×2 L | X Axis Range | 600 mm |

| Dimension·Length | 3700 mm | X Axis Max.Speed | 350 mm/s |

| Dimension·Depth | 1750 mm | X Axis Repositioning Accuracy | ≤0.05 mm |

| Dimension·Height | 2800 mm | R Axis Range | 150 mm |

| Main Motor Power | 3.9KW × 2 | R Axis Max.Speed | 150 mm/s |

| Throat Depth | 400 mm | R Axis Repositioning Accuracy | ≤0.05 mm |

| Open Height | 460 mm | ||

| REMARK: Subject to alteration. Only specifications in our offer and order confirmation are binding. | |||