What is a laser machine?

What is a Laser Machine: Harnessing Light for Precision and Efficiency

In today's technologically advanced world, laser machines have become indispensable tools across various industries. Whether it's cutting, engraving, marking, or welding, laser machines offer unparalleled precision and efficiency.

But what exactly is a laser machine, and how does it work?

At its core, a laser machine is a device that utilizes the power of lasers to perform a wide range of tasks. It combines the principles of laser technology with precision control systems to achieve highly accurate and controlled material processing.

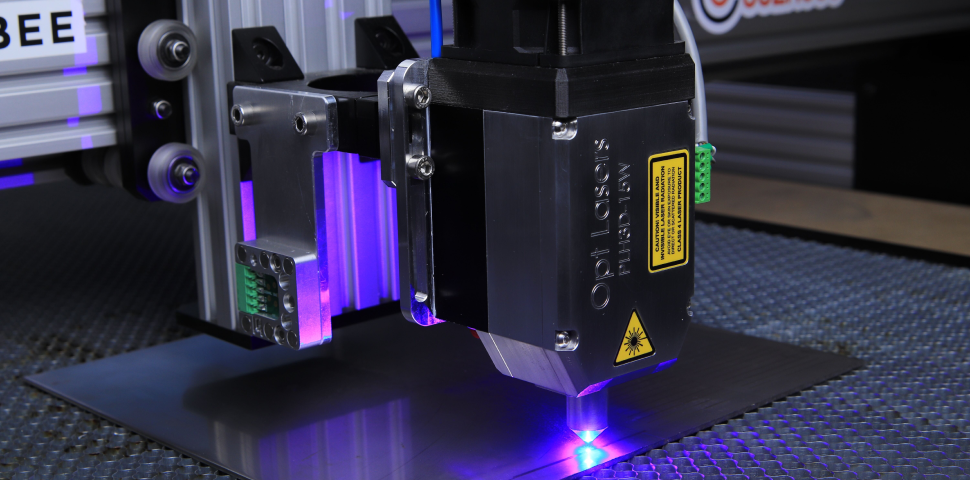

The heart of a laser machine is a laser source. This laser source generates a high-energy laser beam that is then focused and directed towards the material to be processed. The laser beam carries a tremendous amount of energy in the form of photons, which are particles of light.

The laser beam used in laser machines is typically produced by solid-state, gas, or fiber lasers. Each type of laser has its own unique properties, allowing for different applications. For example, solid-state lasers, which use solid crystal or glass as the laser medium, are well-suited for engraving and marking tasks. On the other hand, gas lasers, such as carbon dioxide lasers, are often used for cutting and welding due to their high power output.

Transform Your Small-Diameter Tube Processing with the R1—Contact Us for a Demo!

The laser beam emitted by the laser source is then manipulated and controlled by various optical components within the laser machine. These components include lenses, mirrors, and galvanometer scanners. Lenses are used to focus the laser beam to a specific spot size, ensuring precision and concentration of energy. Mirrors are employed to redirect and guide the laser beam along a desired path. Galvanometer scanners enable rapid and precise beam positioning, allowing for intricate and detailed work.

The material processing capabilities of laser machines are diverse and extensive. Laser cutting is a popular application, used to cut a wide range of materials such as metals, plastics, wood, and fabrics. The intense and concentrated laser beam melts or vaporizes the material, creating clean and precise cuts with minimal heat-affected zones.

Laser engraving and marking are also common applications. By removing or altering the surface layer of a material, laser machines can create permanent marks, logos, or designs with exceptional precision. This makes them ideal for personalization, branding, and product identification purposes.

Additionally, laser machines are widely used for welding. Laser welding offers numerous advantages over traditional welding methods, including high precision, minimal distortion, and reduced heat input. It is employed in industries such as automotive, aerospace, and electronics manufacturing, where strong and reliable welds are essential.

One of the key benefits of laser machines is their non-contact nature. Unlike mechanical cutting or engraving tools, laser machines do not require direct contact with the material being processed. This eliminates the need for clamping or fixing the material in place, reducing the risk of damage or distortion. It also enables the processing of delicate or fragile materials that may be difficult to handle using conventional methods.

Upgrade to the R2 for Comprehensive Tube Processing Solutions—Inquire Today!

Moreover, laser machines provide exceptional repeatability and accuracy. They can execute intricate patterns, complex geometries, and fine details with remarkable consistency. This makes them invaluable in industries where precision and quality are paramount, such as electronics, jewelry, and medical device manufacturing.

Safety is a crucial aspect when working with laser machines. The intense laser beam can pose risks to the eyes and skin if proper precautions are not taken. Laser machines are equipped with safety features such as enclosed work areas, laser safety interlocks, and beam shut-off systems to ensure operator safety.

In conclusion, laser machines harness the power of lasers to achieve precise, efficient, and controlled material processing. With their diverse applications in cutting, engraving, marking, and welding, laser machines have transformed industries and revolutionized manufacturing processes. Their ability to provide exceptional accuracy, repeatability, and non contact processing has made them indispensable tools in various fields.