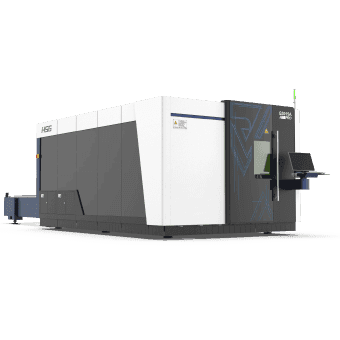

GA IV Series

Double exchange platforms laser cutting machine (1500-6000W)

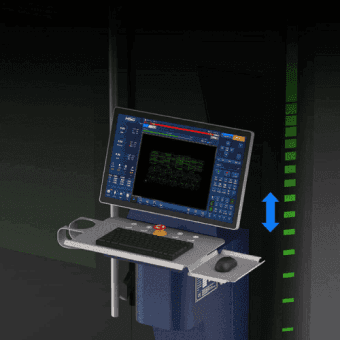

- Alpha T Bus CNc System

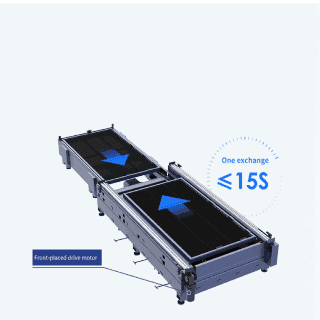

- Double Exchange Platforms

- The latest generation of extruded aviation Aluminium Beam

Double exchange platforms laser cutting machine (1500-6000W)

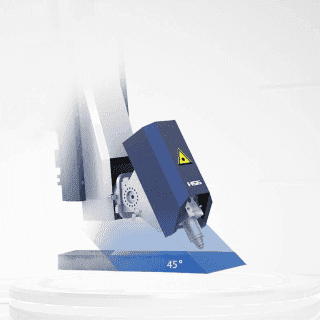

Our self-developed high-power laser cutting heads work with FANUC 3D five-axis control system to break through conventional 0° straight section and make 45° bevel possible. V-, X- and Y-shaped bevel can take shape only once, which helps to reduce working procedures and enhance cutting efficiency.

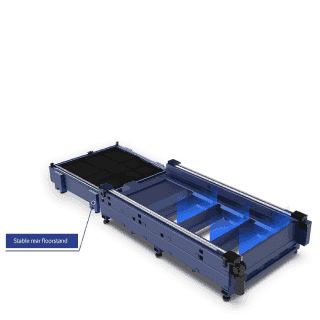

The machine bed is featured by less heat absorption, rapid heat dissipation and deformation prevention, which will remain stable even after long-term working at high speed. The rear floor stand has the reinforced loading points and better bearing capacity, making long-term batch and stable cutting of thick sheets possible.

Optional Features:

Alpha T, self-developed by HSG LASER, can make data transmission rapid, stable and accurate only via a network cable as a technically advanced bus system.

With powerful blower fans and 300*300mm large-caliber air ducts, cutting smoke will be discharged smoothly and the work environment becomes cleaner.

Optional Features:

| Feature/Model | G3015A IV | G4020A IV | G6020A IV | G6025A IV |

|---|---|---|---|---|

| Working Area (L*W) | 3000mm*1500mm | 4000mm*2000mm | 6000mm*2000mm | 6000mm*2500mm |

| Stroke (X/ Y/ Z Axis) | 1524mm/3048mm/270mm | 2025mm/4050mm/270mm | 2025mm/6025mm/270mm | 2525mm/6025mm/270mm |

| X/Y Axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| X/Y Axis Repositioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Max. Moving Speed | 140m/min | 140m/min | 120m/min | 120m/min |

| Max. Acc. Speed | 1.5G | 1.5G | 1.5G | 1.5G |

| Laser Power | 1500W~6000W | 1500W~6000W | 1500W~6000W | 1500W~6000W |

| Max. Loading Weight | 800kg | 1000kg | 1800kg | 2300kg |

| Overall Dimensions (L*W*H) | 8850×2950×2250mm | 10300×3460×2250mm | 15420×3460×2250mm | 15500×3960×2250mm |